How to Cut Crown Molding Laying Flat – With Easy Reference Templates

This tutorial explains how to cut crown molding flat, on any miter saw (provided your molding isn’t wider than your saw’s cutting area). It’s easy to get confused about which side of what corner you’re cutting by the time you take your length measurement and get to the saw. Creating a set of templates will give you a visual guide that you can use in the room to mock up the corner you’re working on – and take with you to the saw.

*This tutorial assumes you have 90° wall to ceiling joints and wall to wall joints. If you are working with a funky wall corners or vaulted ceiling – this tutorial will not be helpful.

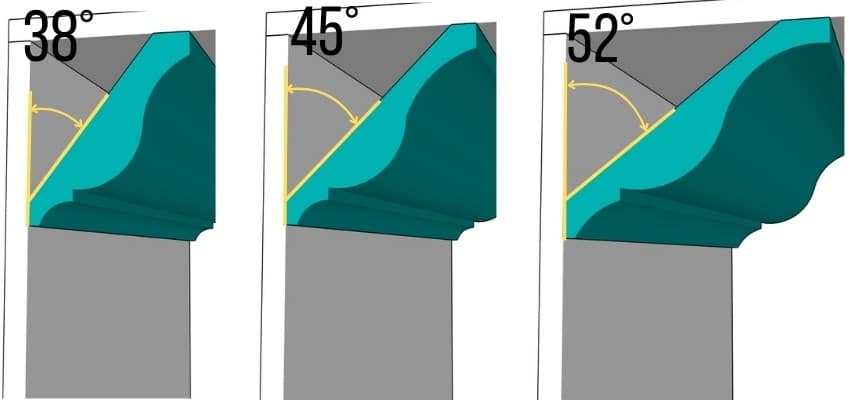

Spring Angle

First off, it is important to understand that crown molding is manufactured with varying spring angles. It is essential to know the spring angle of the crown molding you are using because it determines the saw settings you will use to cut the molding. Check out this post if you need help Finding the Spring Angle of your crown molding.

Saw’s Miter and Bevel Settings

I am demonstrating settings for 38° spring angles in this post. If you need to create templates for 45° or 52° spring angles, use the appropriate substitutions below.

45° Spring Angle Substitutions

Crown molding with a 45° spring angle is traditional choice, great for ceilings 9′-10′ heigh.

- Left bevel set to 30°

- Miter cuts will be R and L 35.3°

52° Spring Angle Substitutions

52° spring angle crown molding is generally chosen for heigh ceilings, 10′ and above.

- Left bevel set to 25.8°

- Miter cuts will be R and L 38.2°

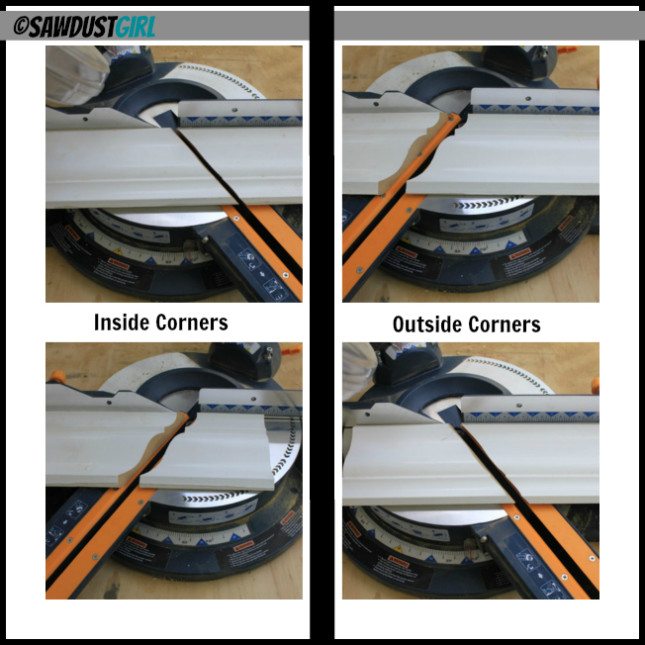

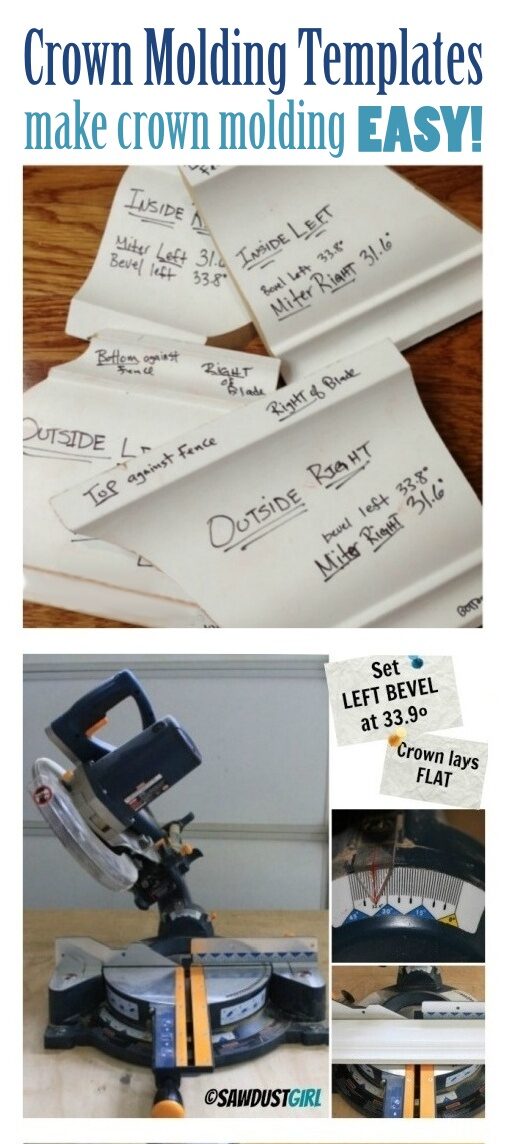

Constants

These two things will be true for every cut:

- The left bevel will remain set to 33.9• for every cut. (Your saw might say 33.8 – and that’ll do just fine.)

- The backside of the crown molding will always lay flat on the saw surface.

Variables

These two things will change depending on the cut you are making.

- The miter will flip between left and right – but always at 31.6•.

- The edge of the molding that rests against the fence will flip between top and bottom. (Remember the decorative edge is the bottom.)

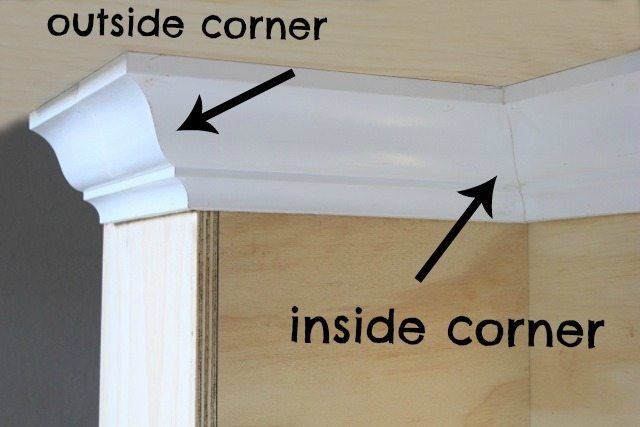

Inside Corners – Outside Corners

The reason crown molding gets so confusing is because you are accounting for the angle between the wall and ceiling and the angle between the wall and wall for every cut.

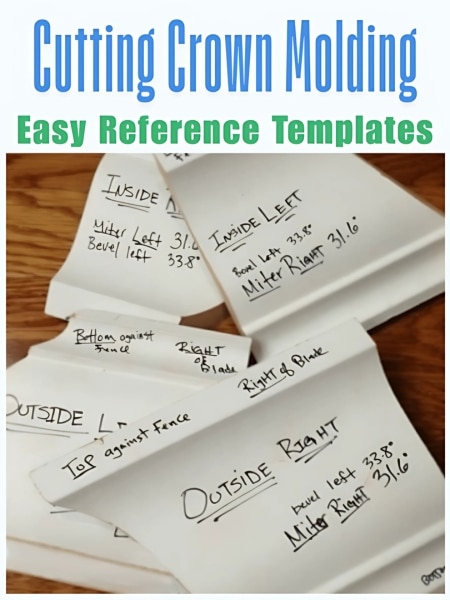

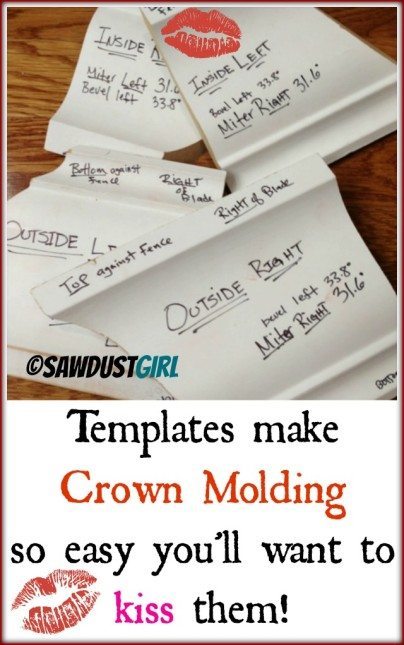

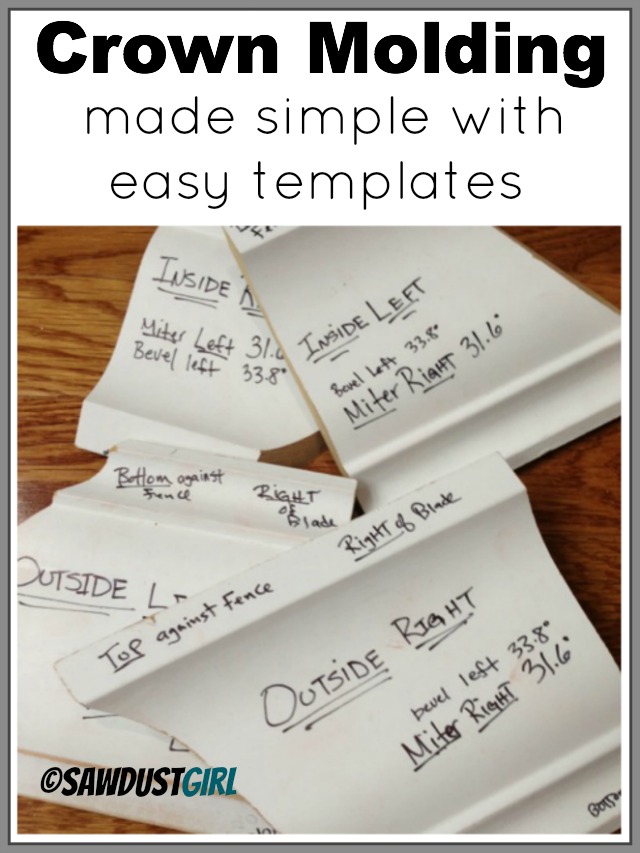

Make your Crown Molding Templates

Cut each template about 8″ long.

Remember that you will only flip your saw between right and left miter – AND flip your crown so the edge that rests against the saw fence changes.

Cut each template according to the instructions I’ve included below each picture and then write the instructions directly onto each template. In SHARPIE!

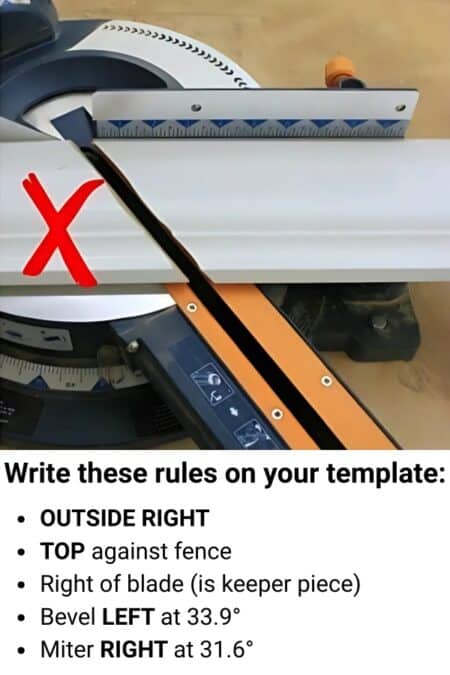

Outside Right

Outside Left

Inside Right

Inside Left

Now you should have four of your very own crown molding templates that are going to make your job so much easier!

I’ve been doing this for a good long while and I still need templates. My brain is very visual. It doesn’t translate, “left outside corner” into any kind of usable information. I HAVE to look at my visual guide – EVERY SINGLE TIME. They’re still handy after all these years!

Also, if you corners are out of square, you’ll either have to make micro adjustments to your saw settings to get a perfect corner joint– OR, you can use my little trick to fix gaps that you might end up having.

I know you posted this awhile ago but I am new to the world of crown molding and was looking for something exactly like this. I actually spent like two hours making my own templates today and these are soooooooo helpful. The first one I made, I stared at it for like 30 minutes thinking THIS CAN’T BE RIGHT but lol it was. Having these as a reference was a real game changer. Thanks for posting such clear instructions.

Hi

I have been doing trim for a long time but I to need to refresh myself before I get started.

This is the best description and with pictures too.

Tommy Silva needs to understand that most people need clear visuals.

Thanks again

Steve

The point of this method is to create compound mitered joints. Using a coping saw to remove the profile off one side of the joint so it fits over the other piece of moulding is a whole different method.

You still need a coping saw.

Thank you so much. This is perfectly clear and wow you the best.