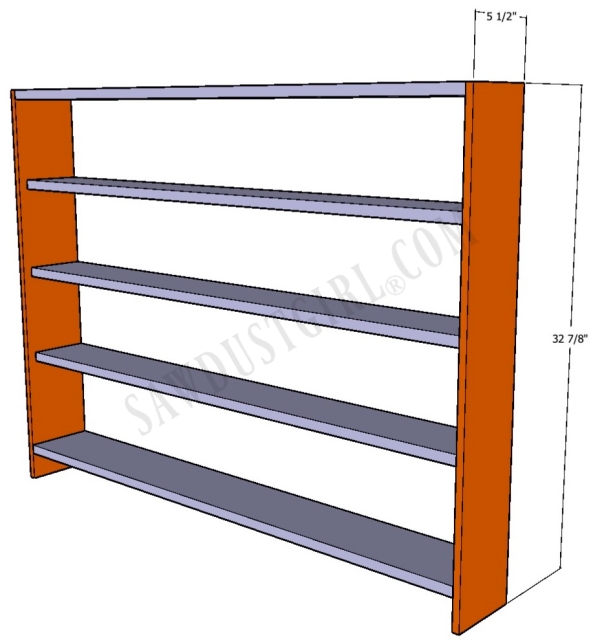

Wrapping Paper Storage Cabinet Plans

This wrapping paper storage cabinet is a simple build but it holds a lot of importance. It’s a support for the craft island. It stores wrapping paper and it houses power outlets on both sides.

Building a Wrapping Paper Cabinet

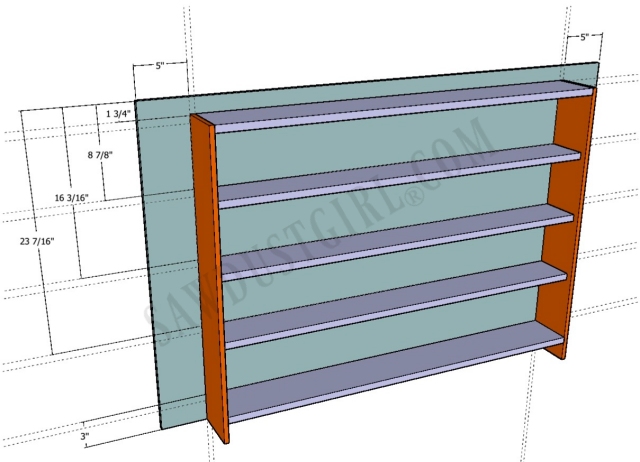

I built my wrapping paper cabinet and attached it to a “half wall” that I built purely to bring the Romex out to the wrapping cabinet. You’ll notice the cabinet top, sits down about 2 1/2″. This space is for the Romex, so both sides of the cabinet have power.

Materials

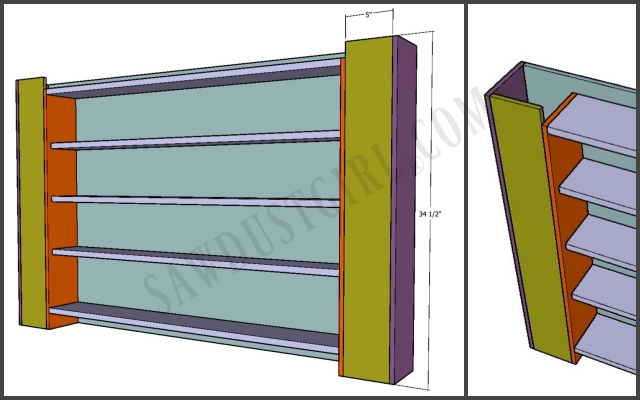

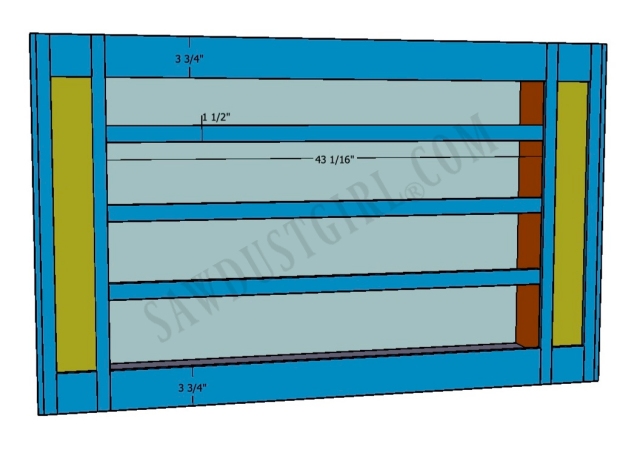

I used a combination of 1/2″ and 3/4″ plywood for this cabinet. Attach and secure with 1 3/4″ SPAX hardwood/mdf screws or 18 ga nails.

The horizontal pieces are all 3/4″, the rest is 1/2″.

Drawing grid lines on the front and back side of the “back” will help you keep the shelves straight, and know where to drive your screws.

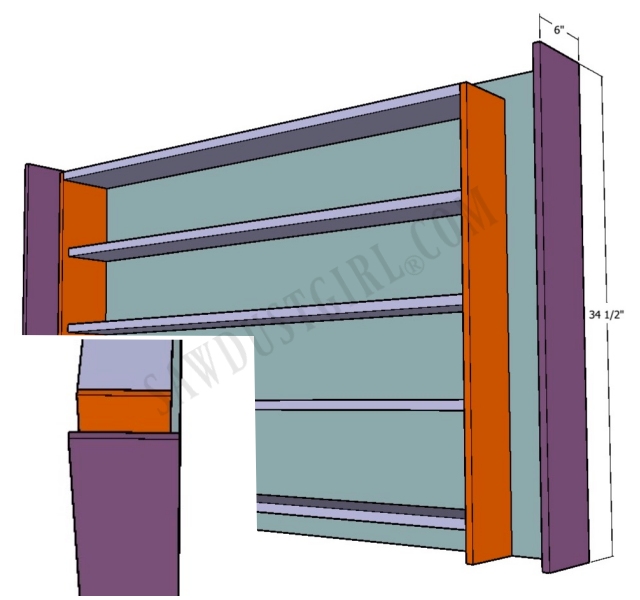

I cut the holes for the receptacles in side panels before attaching them.

The front panels could be another place for receptacles, depending on the layout of your craft room or where this cabinet will be sitting. Just plan ahead for those receptacles.

The power comes into my wrapping cabinet through the back, into one of the side columns. Then it runs through the space at the top to the other side.

The 1 1/2″ pieces to the frame facing this cabinet can be 1×2 pine or rip all the frame pieces out of plywood or MDF. Just sand and fill the edges before installation to make it easier to paint once it’s all built. The frames for the shelves are flush with the shelf bottoms, creating a 3/4″ lip on front of each shelf. This keeps wrapping paper from rolling off the shelf.

The countertop acts as the top of this cabinet. If you were to build it as a stand alone cabinet, you would simply add a top. I would either have it sit flush with the cabinet edges, or protrude by about 1″ on the front and sides.

In my set-up, the countertop is not secured to this cabinet. This cabinet is secured to the cabinets behind it and then the countertop is secured to those cabinets through their top cleats.

We had to add a small piece of moulding at the bottom of my cabinet because of the gap left after installing the Pergo floors. I wouldn’t do this by choice. Though it looks pretty, that moulding is probably going to get stepped on or kicked…possibly frequently. Maybe it won’t be a problem at all but I don’t like adding protrusions in standing work areas. Toe kicks are preferable but this cabinet is very shallow so it would have just looked weird. It is what it is on my cabinet. Just putting that out there for anyone planning their own craft room paradise.

You can download the full plans which include a cut list and full page diagrams with instructions for assembly. They’re free.

Everything you do is very inspiring. Loved how everything looked after it was completed. However, you did even better by thoroughly detailing the entire process of building the cabinet.