Installing WoodHaven Planks and Hiding Drop Ceiling Grid!

Guys, I’m so excited! Look at the new ceiling in my Piano room! What a big improvement over the unsightly acoustic tile, suspended ceiling that was there before! This ceiling was SO easy to install and I didn’t even have to take down the grid! I installed WoodHaven Planks from this post’s sponsor, Armstrong Ceilings, right onto the existing grid.

Before

You remember what this room looked like before, right?

When I showed you guys the house tour, everyone commented on the drop ceilings. Apparently, a lot of you have them in your basements. I see them all the time in schools, medical buildings and commercial spaces, but I’ve never seen them on a main level of a residential home –before now.

A few months after the house tour, I got an email from Armstrong Ceilings about their product, WoodHaven Planks. When exploring their website, I saw the planks could be used on drop ceilings–AND that you can install them onto a drop ceiling grid! Life changing!

I’m not ready to tackle my whole house right now but we need one pretty room in this house! We need a space to escape from the rest of the “not our style” house. The Piano room made the most sense for this quick makeover.

Installation Video

Easy Up Clips

The magic of this system is in the Easy Up clips which fit onto a 15/16″ grid. The Easy Up clips snap onto the grid and have a hook that slides into the groove on the planks to secure them. When the ceiling is finished, there aren’t any visible fasteners or nail holes to fill.

A great thing about the clips is that you can install and remove the WoodHaven planks easily; if you make a mistake (or realize you need to resize your light hole for the third time), you can just back the clips up, take the piece down, and go trim the piece again. Awesome!

Installing WoodHaven Planks to Drop Ceiling Grid

For the first row, I used a laser level to ensure the whole row ran in one solid line. Then, I secured these planks to the grid with screws so they wouldn’t move around as I tapped subsequent rows in place.

Once that first row was in, the rest of the planks tapped into place really easily. And pretty quickly. All by myself! One person ceiling installation is a game changer. The planks are 84″ long and I could install one full plank all by myself without moving the ladder, if I place it correctly.

When I did have to move the ladder (a couple times), I just pushed the clips in on the right side, got down and moved my ladder, then pushed in the rest of the clips.

Vents

There are two vents in this room. Obviously, I wasn’t going to use the existing, big, 2’x2′ drop ceiling vents!

A traditional vent is more aesthetically pleasing, IMO.

The suspended ceiling (and attached planks) can’t support any substantial weight so ducting needs to be suspended with 12-gauge hanging wire.

Switching out from the 2×2 square, drop-ceiling, vent to a normal looking vent wasn’t that difficult!

- I cut through the mess of tape on the flexible ducting to create a clean end

- Pulled back the outer layer and insulation

- Attached the inner liner to the vent boot with a heavy duty zip tie

- Secured that joint with metal foil tape

- Pulled the insulation and outer layer back down and secured it to the boot with another zip tie

- Covered, reinforced, and sealed that joint with more metal foil tape

I attached a block of wood to the vent to keep it positioned, flush with the planks. In hind sight, I probably didn’t need to because once I screwed the grill in place, it would have held the boot in place….but anyway).

I also held a scrap of wood above the planks while driving in the screws that secured the vent cover. The screws that come with those covers are about 3″ long and the planks are less than 1/2″ thick. I wanted some extra material to drive those long screws into. (It’s not pretty but it did the trick.)

Lights

The previous light situation included; two, 2’x4′, fluorescent lights on two separate switches, as well as seven can lights. Three on the left and four on the right that were each operated with their own switch. I had my electrician come in and give me ONE dimmer switch to control all nine of the new, integrated LED, canless lights I installed.

Typically, lights would need to be independently supported by something other than the ceiling planks. I didn’t really want to deal with all that hassle, so I ordered some lights that would lessen the load… These recessed lights are very light so I didn’t need to suspend them from anything! All I had to do was set them in through the hole and rest them on the planks. Then, I snapped the trim kit in place, and voila!

Well, I shouldn’t say voila like it was that easy…It wasn’t THAT easy. I had to cut all the holes before installing the planks. I put tape on the grid to remind me of the general location of where I wanted a row of lights. Then when I got to that area I:

- put up a couple rows of planks

- measured and marked the location for the three lights in that row

- took those rows of planks back down

- cut out the holes

A few times I had to remove multiple rows of planks to resize holes because I hadn’t made them quite big enough. There’s not a lot of leeway with the trim. You can’t cut the holes too big or you might have to use some caulk to zshoosh the hole… I’m not saying I did, but I’m not saying I didn’t.

I installed the lights, centered between two adjoining rows of planks — to make it easier to cut the holes. After marking the center for each light, I used a paper template to draw the correct size circle. I cut the holes using a jigsaw.

This technique made it easy for me to cut out the holes, even if it made the spacing between lights not EXACTLY symmetrical. There’s enough space in between the lights that I don’t have to worry about a couple inches difference.

Clip Spacing

When installing the planks, the clips have to be installed on the grid that is perpendicular to the planks. Each row of planks should be secured with a clips on every perpendicular grid line. In a couple locations, the cross braces were in the way so the clips couldn’t slide into place. I just took those pieces out.

Final Touch

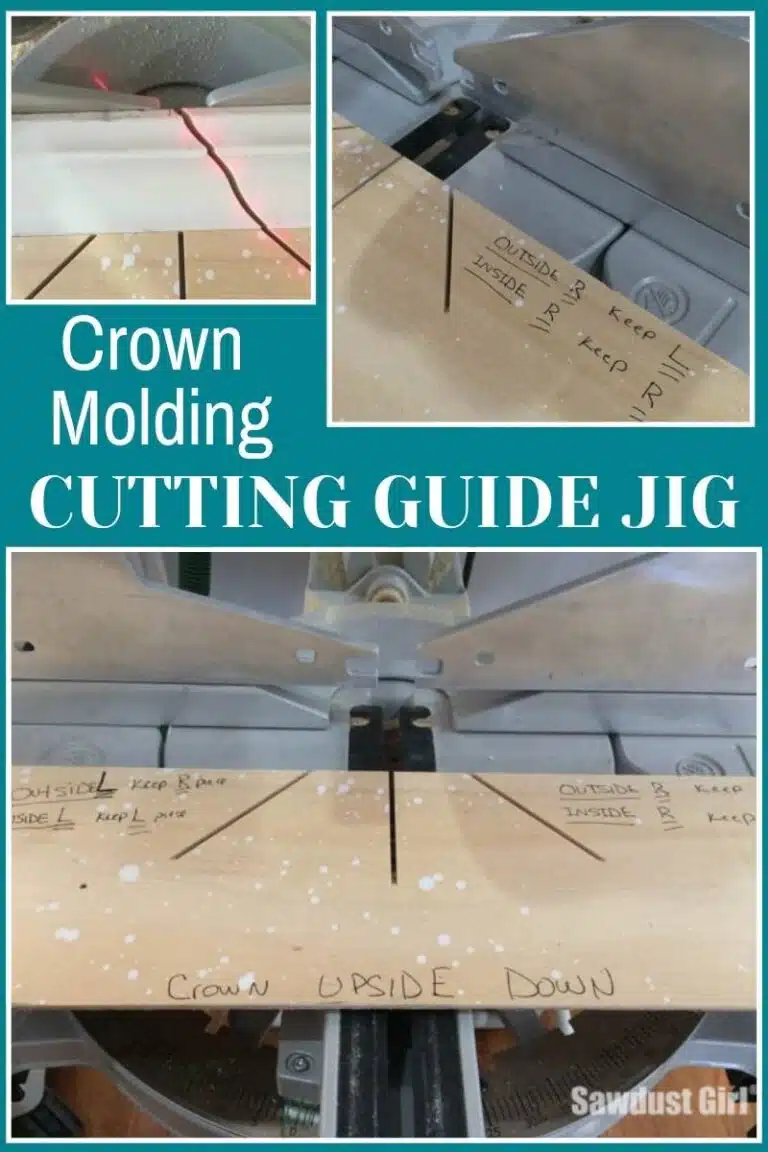

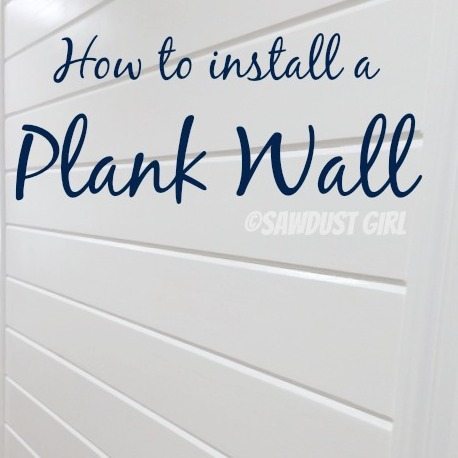

One thing to note is you have to leave expansion gap around the perimeter of the room to allow for contraction and expansion. In addition to being a lovely, architectural detail, crown moulding hides the expansion gap and supports the planks around the perimeter of the room. Although I did install the whole ceiling by myself, crown moulding is a two person job (for me) so Julie helped me with that.

The WoodHaven planks come in a variety of finishes. They are pre-finished, so no need for painting or finishing. You just put them up and Boom, you’re done.

I chose WoodHaven Classic White because, you know me and white ceilings. I like the look and feel of the real wood grain on the Classic White planks.

Finished! (but for art and furniture…)

So, here is the progress on the piano room so far:

- A fresh coat of paint made a big improvement.

- New ceilings are a HUUUUUGE improvement.

- New, normal looking vents.

- Much better lights (on a dimmer switch to create ambiance in the evening when someone is giving us a piano concert). Woohoo!

Even though it’s not actually furnished, I can go into my beautiful room and sit on the sofa or play the piano, and just enjoy! I won’t even let myself be bothered by the windows, which are oddly high. Eventually we will add on a new wing to this house and probably change a lot of the existing space and make the whole house more…our style. Because we don’t yet have a “big picture” plan for this house we aren’t doing any major renovations. This “room redo” made a world of difference without any major demo. Wes is especially happy about that!

I can’t wait to bring in some art, a rug, and additional furniture to create a little oasis of loveliness in our odd little house. The transformation of this room almost makes me shed a happy tear. After moving out of Richwood, right after making it reaaaaly beautiful, it’s nice to have one beautiful space in this house.

Big thanks to Armstrong Ceilings for partnering with me on this room makeover!

Check out more of my Ceiling Projects

- Whitewashed pine ceiling I installed in the Lodge

- X shaped Box beam ceiling tutorial

- Faux V-Groove plank ceiling I put in my previous craft room

- Build and install a Faux Wood Beam on the ceiling

I installed thin LED wafer lights. I haven’t done anything with the ceiling since installing it and we absolutely love it. Like with drywall, the area above this ceiling isn’t accessible without work. I don’t anticipate ever needing to access the area above my ceiling so that wasn’t an issue. It is a consideration for some though so good to be aware.

Hi. It’s almost 2023 so hoping you see my comment.

First of all – BRAVO! Wonderful job!

I have a lovely – and by lovely, I mean HIDEOUS, 70’s drop-in ceiling in my basement which has been completely redone – except for the ugly ceiling. Installing drywall is just too big of a job so.

Originally I was going to purchase new and improved drop-in tiles which come in a wide vareity of colors and designs now. But those new tiles are thin PVC. Someone mentioned she lit a candle in her “new” room and it turned those new tiles yellow! So yeah – NO!

Then I found theses Armstrong planks – which can be installed in a variety of ways including using your existing suspended ceiling grid. I just ordered some samples of the planks in various colors and the clips. If the clips don’t work on my grid – back to the new PVC tiles I go.

The planks are way more expensive than the drop-in tiles. Both look simple to install – except for registers/lights, etc. So will have to hire someone to do that for me.

What kind of lights do you recommend? Is there anything, good or bad that has changed after your install?

Thanks!

No, there isn’t access above without removing the planks. The good thing is there are no nail holes (except on the perimeter under the crown) so the planks can go back up after dealing with the issue… Unless there was water damage which is the only reason I’ve ever ripped out a drywall ceiling. In which case I had a huge drywall mess to deal with.

Do you still have the option to access behind the ceiling? We were looking to install this in the basement instead of Sheetrock to still be able to access pipes and ductwork in an emergency. Curious if you would have to take the entire molding out and then the entire thing down until you got to the problem if there was one…

It’s been a couple years since I did this project so I don’t remember but I probably didn’t read that part of the instructions. 😉