How to hide seams in Beadboard

I often install beadboard to the sides of built-in cabinets in addition to using it as a decorative element on walls and ceilings. The most cost effective beadboard material I have found is 4×8 paneling sheets found at most home improvement stores. If 8′ isn’t tall enough, you have to install multiple pieces and the butt joints are pretty obvious. You can hide the seam with trim or some wood putty and elbow grease.

1. Select the Right Material

Beadboard paneling comes in 1/4″ thick MDF or plywood sheets. The size of the bead and width of the V-groove will often vary by material or even sheet to sheet of the same material. The most important thing to pay attention to is making sure the grooves and beads line up with each other when you stack them, end to end.

2. Attach beadboard firmly to surface

Make sure the beads and grooves line up as perfectly as you can get them before securing them. in addition to brad nails, I use caulk as adhesive. It may not be necessary to use adhesive on the entire panel, but apply it on the area where the seam is being created. The objective is to prevent future movement and cracking in the wood putty which would reveal the seam.

If applying to a wall, use adhesive on the whole sheet, adding nails where you have studs.

3. Apply wood putty

Apply your favorite wood putty generously, making sure to press it into the grooves and fill all the nail holes. In order to build up a strong patch over the seam, spread on an ample supply of wood putty. Then use a wide putty knife to feather it out, sreading a portion of putty both above and below the seam. Feathering it out and spreading the wood putty over a larger area will help hide the seam.

4. Clean wood putty out of grooves

Use the corner of a putty knife to scrape the putty out of the grooves. In some areas you may find that this action reveals the seam. If this happens, reapply putty in that area and take less out when scraping the groove. You may have to use your fingers to shape and round the wood putty over the beads.

5. Sand face and grooves

Face

Wait for the putty to be completely dry before sanding. The flat face of the beadboard can be sanded with a fine grit sanding block or using an orbital sander. Either way, use gentle pressure and only take off a little at a time so you don’t remove too much putty and reveal the seam.

Beads and Grooves

I like to wrap a putty knife is sandpaper to create a thin, stiff, and flat sanding block. (I start with 120 grit sandpaper followed by 220 grit.) Using a gentle up and down motion, sand all the beads and grooves. You’ll probably have to reposition the sandpaper frequently because there is such a small area of sandpaper surface being used.

6. Decide if you can move forward or need to repeat a few steps

Once the whole seam is sanded smooth, look at it with a critical eye from multiple directions. Decide if it looks really good or needs another coat of wood putty. If it needs another coat, go back to step 3 and repeat.

7. Prime

If it looks great, prime it. The primer will accentuate any and all imperfections. If any imperfections are revealed that you don’t want to live with, repeat the necessary steps to hide the seam to standards you can live with.

8. Paint

Once you decide the hidden seam looks great, go ahead and paint the beadboard.

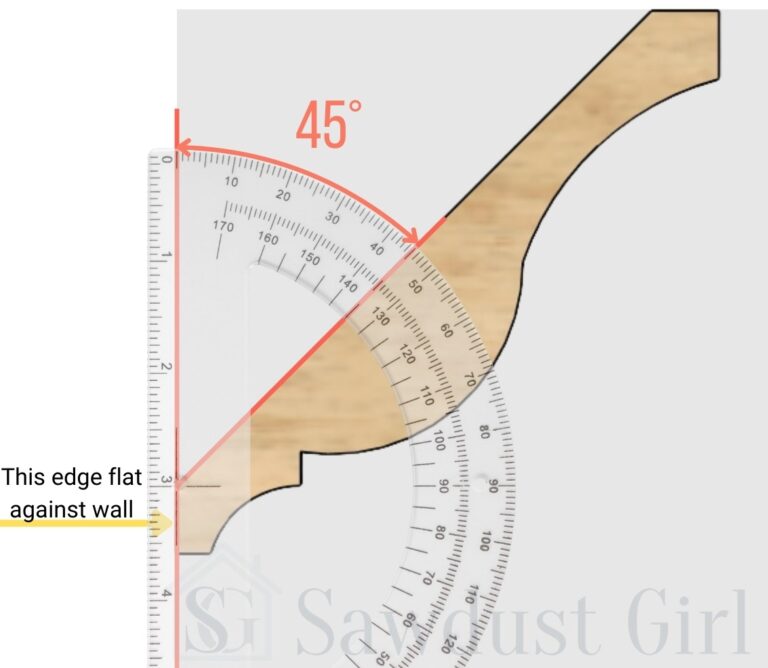

Tip: If after painting you see a visible hairline crack, scraping the paint with a one sided razor blade might do the trick. Hold the blade at close to a 90 degree angle and gently scrape across the crack/seam. If the first pass doesn’t do anything try again with a little more pressure. This trick only works with very small seams.

If you’re still not happy with the hidden seam, you can keep perfecting it until you’re happy with it.

Finally someone has shown me how to do this! THANK YOU!

First of all I have to say, YOU are a rockstar!!!! Thank you for all of your amazing tutorials. I only hope to learn more from you in future:) I do have a question for you on finishing your beadboard. In the top two pictures above, the after picture shows a strip hiding the seam of the inside corner where the beadboard butts up agains the cabinet. Where do you get that and what’s it called? I did beadboard on an end cabinet that covers the side of the refrigerator and I have a gap between the wall that it butts against and I don’t know how to find a really thin piece that will look nice and hide the imperfection without using shoe molding or something clunky. Thank you!

Thanks Barbie. That little strip is a piece of picture frame moulding from the big box store.

Hi there! Thanks for all the great information! I have a slightly different question. I have a ton of headboard panels in my home and I’m looking to work more of a board & batten look. Can I use the same products that you suggest in this article to permanently fill the grooves in the existing bead board with the overall goal of making it smooth? Any suggestions in doing that?

Thanks a million!

Lindsay

Possibly but that would take A LOT of wood filler and if it’s painted with a glossy paint, would it stick permanantly? It might be less work and expense to cover the beadboard with a very thin, smooth panel like 1/4″ plywood or MDF.

Thank you so much for doing this article. A previous homeowner installed the exact beadboard you showed in the two-car garage / master bedroom conversion floor to ceiling in bedroom, closet, hallway, master bath and the laundrey room. (What a pain to prep for painting! took me a day of filling nail holes, another day to sand the putty, then several days of priming and painting – and that was only putty/sanding the master bedroom – with priming/brush painting only one wall before I quit and that was several years ago – still waiting on a hero to come in and finish them all for me!!) Anyways, the guest bathroom I changed out the vanity which had a 4″ backsplash glued to the wall so of course there are huge gauges in it that I couldn’t fake fill it. Eventhough I’ve decided to just add another backsplash could you advise we readers on how we might fix any big repairs? And what your thoughts on maybe making my floor to ceiling beadboard look like a chair rail style by filling in all the lines from 36″ up in a similar way you did your repairs here except not scraping out the lines, just sand smooth and add horizontal rail moulding? I’m thinking that would be less of a hassle than covering or removing the upper portion of a whole room. P.s. Another question is how are the corners where two walls meet supposed to be treated when doing beadboard walls *and* ceilings? I don’t think they used the correct mouldings in the corners where the ceilings and walls meet. Thank you again for sharing your extensive knowledge!

I don’t think there is ever one way to do anything. I think of most things as an experiment (if not structural) and just try something. If I don’t like that I’ll try something else.

-if I were creating a floor to ceiling beadboard wall in a large room, I’d create a grid so I didn’t have any horizontal seams to hide.

-When you remove glued on wall coatings and the drywall paper tears, prime those areas with an oil or alcohol based primer before “mudding”.

-I just butt one wall up over the previous and then caulk the corner. I like crown moulding so that’s what I would use at the ceiling but you can get creative and do 100 different things.

Experience comes from doing and the more you do the more confidence you’ll have in trying the next project.