Selecting the right types of wood for your DIY project

I get asked a lot, what types of wood I use to build a cabinet base, cabinet door, trim, furniture and the list goes on. There are quite a few different options to choose from and today I’m going to go over the basic materials that you can find in any big box store as well as most lumber yards. I’ll let you know what type of material I use on different projects and why.

Selecting the right types of wood for your DIY project

Soft Wood: Pine 1x Material

Pros:

- It’s cheap, and versatile

- Easy to cut, glue and has good nailing and screw holding properties

- Comes in a wide range of widths and lengths.

- 1×2,3,4,6,8,10, and 12 inches at 3,4,6,8,10 and 12 ft lengths

- Easy to paint and stain.

Cons:

- It’s a very soft wood, marks easily.

- It can come out splotchy when staining if not approached correctly. (Check out this helpful post on how to stain wood!)

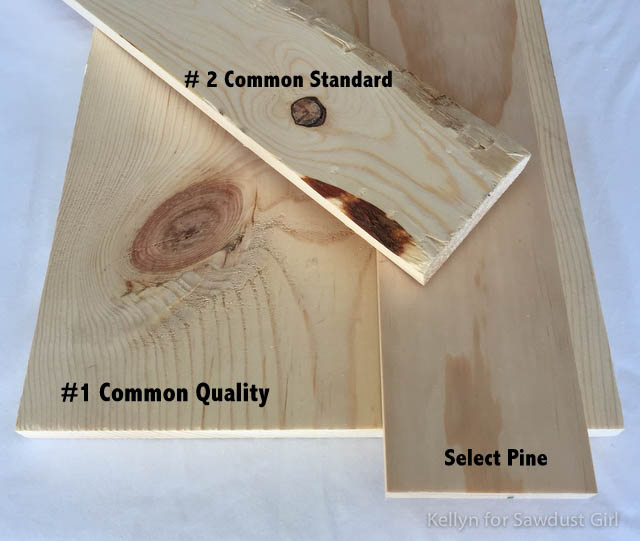

Pine comes in 3 Universal Grades:

Sheet Material:

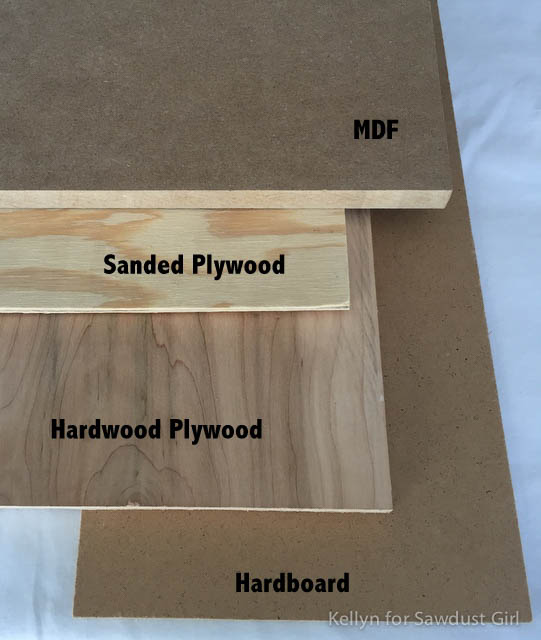

MDF, plywood, hardboard

This is what most of your cabinet carcass, drawer bottoms, shelving etc. will be made out of. Every builder I have ever talked with has their preference (and sometimes strong opinion) of using MDF vs plywood. I personally love and use both in different circumstances.

MDF

Medium-density fiberboard ($48 average price of 3/4in 4x8ft sheet. Also comes in 1/2″ and 1/4″).

Lets talk MDF first, because I think it gets a bad rap. Yes, it’s cheap, extremely heavy and made of condensed and glued sawdust, but it cuts** like butter and paints like a dream. (And yes, if you do it right, the edges paint up nicely too!)

(How to paint MDF and get smooth edges)

**Always use a mask while cutting wood and sheeting material, but especially for MDF. This dust should NOT be inhaled.

When it’s painted, you can’t tell if it’s MDF or Wood. Can you tell which door trim is made of Select Pine and which one is from a sheet of MDF?

The cost difference is significant. $0.65 per linear ft for the Select Pine board, but when I cut down a 4x8ft sheet of MDF it’s only $.29 per linear foot. Yes, I still have to sand down the edges and prime and paint. But the cost savings to me beat the worktime – most of the time. Especially if I do a big batch at once.

But here’s the catch about MDF. The moment it comes in contact with moisture it bubbles up and is defected forever. There are some that say if you prime and paint the MDF so it will not soak up the water, it will be fine… But honestly I will not use MDF in the kitchen, bathrooms or around windows, and instead painted Select Pine boards. To me the risk isn’t worth it.

Plywood

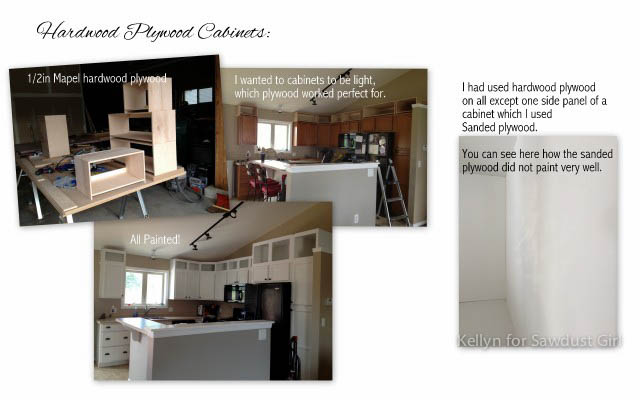

Next is plywood. There are different grades of plywood, just like pine boards. But we are going to focus on Cabinet Grade Plywood since that’s really the only plywood I use for cabinets and built-ins.

Cabinet Grade Plywood

Cabinet grade plywood is the best option for cabinets and furniture builds. It’s a the alternative to MDF for a cabinet carcass. You can commonly find Birch, Hickory, Oak and Maple hardwood faced plywood at the big box stores and can order any species you like.

So here’s the thing…

If you plan on painting your cabinets inside and out, to save some money in your budget for some “bling-bling” – by all means, MDF is a great choice.

BUT-

If you want to leave the interior cabinet carcass natural or stained, plywood is the way to go. Buy a pre-finished plywood if you want to skip the step of applying a protective coating yourself. You can purchased single sided or double sided pre-finished plywood.

Hardboard

Moving onto hardboard, also known as backer-board. I always have sheets of this stuff on hand.

Uses:

- ⅛ inch width – behind batten board for a smooth wall finish, backs of cabinets which also helps hold the carcass square and sturdy.

- ¼ inch width – bottoms of drawers, cabinet door panels or where I would need ¼ width for wall trim detailing.

Hardwood and Trim

Hardwood is what you use for cabinet face frame, cabinet doors, even trim. There are many species of hardwoods; poplar, hickory, birch, oak, mahogany.

I strongly suggest using hardwood for all your face frames and cabinet doors. Yes, it’s more expensive than pine, but pine is too soft and will not hold up a cabinet door for long, and will not hold up to the amount or ware-and-tare cabinets get.

If you are painting your face frames, poplar is great! Staining, not so much… go with a different hardwood species.

So there you have it. Just the basics…

Now lets chat about getting bids from contractors for some massive project that you don’t want to tackle yourself. You get multiple bids and they’re all different. What types of wood does each bid cover?

MDF may be cheaper and is a great option if you decide to have the entire structure painted.

If your bid is for plywood, make sure they are using furniture grade hardwood plywood. It will be expensive but gives you the option to stain or paint.

Make sure the face frames are made with a hardwood like poplar especially if you want cabinet doors. I supposed pine face frames would be fine for display shelves that wouldn’t get much use all the time.

Great article 🙂 I’m thinking of using hardboard (instead of plywood) to do faux shiplap walls and have found some tutorials online that say you can use it for shiplap. You mentioned that a “con” though of hardwood was “do not sand.” Does hardboard have frayed edges when cut? Would I be able to get them smooth? Or do you not recommend using hardboard (cut into 8″ X 8′ strips) for shiplap? Thanks so much!

If you use a very sharp sawblade you can get clean cuts. If you are doing the traditional faux “shiplap”, you will have a small gap between the boards and probably won’t care too much if the edges are smooth to the touch, because no one will ever touch them (once they are on the wall). Most people I know that have done faux shiplap have used hardboard or cheap 1/4″ underlayment, neither of which will have smooth cut edges. It really depends on the look you are going after. If you want a country farmhouse look, I think it’s fine. If you want a more polished look, I wouldn’t do a “faux shiplap” at all.

Great article!! Thank you so much for such detail. No one person has this level of info. Cheers! Will be looking for some popular now to make some doors!

I was wondering some peoples thoughts on MDF around things like windows. I think the same thing, so way will I use MDF anywhere near where it might get wet

Once MDF is painted/sealed, it won’t be effected by moisture (unless it’s saturated in water — that’s probably not a good idea. Lots of pre-primed trim is made of MDF.