How to Build a Wood Floor Countertop

I got lots of questions about my Office wood floor countertop after I posted said that I built it out of Oak Flooring. So, I created some sketches to try to give you a better idea of how you can make all your dreams come true…if you’re wondering how to build counters out of hardwood flooring!

How to Build a Wood Floor Countertop

*I’m purposely not giving you any surface dimensions because you have to build the countertop to fit your work space.

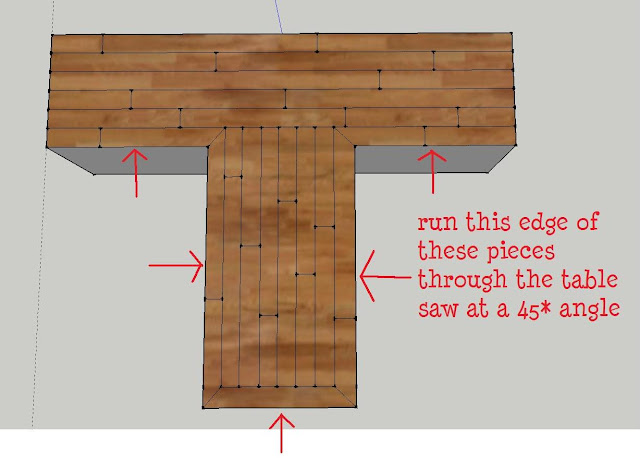

My work space happened to be T-shaped, you could do the same thing with a straight countertop, or L or X or + shaped for that matter!

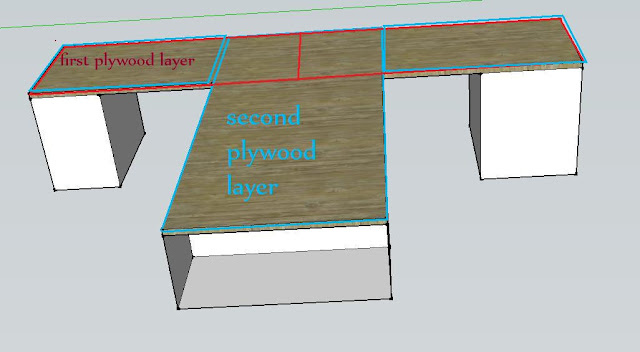

1. Create a plywood base

- Cut a plywood base the shape of your countertop but subtract the thickness of your finish material from the desired final width. (I used 3/4″ flooring for my countertops so I made my plywood base 3/4″ narrower!) Why? Because you are going to put a “face” on your countertop to make it look thicker, which will add to the total width.

- Use two layers of plywood to create a strong base. If you have seams, stagger your second layer so you’re seams do not end up in the same place. Screw both layers together to secure the seams.

- If the ends of your countertop are going to be exposed, do the same “adjustment” for the length. (My countertop goes wall to wall so the ends don’t matter)

2. Attach Hardwood

I used unfinished 3/4″ Oak wood floor material because it was cheaper than buying regular 3/4″ Oak from the lumber store. Plus, the tongue and groove helped secure each row together without using glue and clamps which I would have done had I used regular wood.

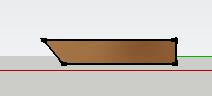

I started on the front and worked my way back. In order for the countertop to appear to be 1 1/2″ thick, I added a 1 1/2″ front edge that was joined with a bevel.

Bevel the first row of wood planks

- Rip enough of your wood floor planks at 45* angles on a table saw. You’ll need enough planks for the whole first row plus a front edge.

- The front edge pieces will need to be ripped to 1 1/2″ wide planks. (My wood was wide enough to get 2 strips out of each plank so I mitered both sides before I cut it to width)

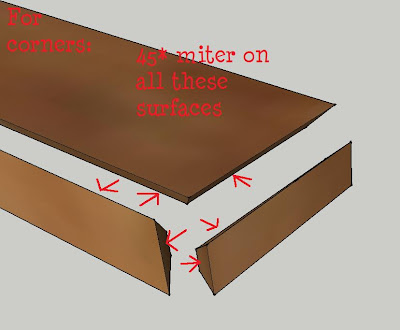

Miter front edge corner pieces

- The corner pieces had to be mitered at 45* angles for the corners as well as the top bevel. I used my miter saw for the end cuts.

Nail wood floor onto MDF countertop base

- I just nailed right through the top since it was unfinished wood. Wood putty in all the nail holes, cracks and corners. The whole thing had to have a good sanding anyway.

- (Make sure you use the proper length nail! I didn’t calculate for that and had to go back after I was finished and pound UP a few nails from the bottom. Don’t want to snag your knees…!)

- Finish! I used (ebony tinted) Tung oil (which I LOVE but make sure you use a RESPIRATOR and the proper gloves if you go that route.)

When using this method for a kitchen countertop,would it be ok to use a water based stain and top it with several coats of poly such as Helms spar or a self leveling type like I see on tables or bar tops? Get back asap as I’m going to buy the lumber to start my new countertops today…. Thanks Sandra, your a doll.

Finishing wood is like creating art. You could do it 500 different ways and no matter what way you choose, you’ll probably always wish you would have done it differently.

After a while, how are your countertops holding up? I’m considering doing a very small (66×18) top to cover an ugly buffet and serve as our TV stand. I think your project looks excellent, and I’m hoping it holds up well also.

We don’t live in that house any more Jen but I had them for 3 years (I think) and they held up great. I wouldn’t use them in a kitchen or anywhere they would get wet because the seams are not sealed well but for an office, they were great.

Hey there. I don’t mean to be the only one with a negative comment but, I have to point out that expansion and contraction are big problems when using flooring for countertops. On your countertops, the problem will show up right at the bottom of the T. Specifically where the miter is. You can’t glue or nail a long grain board perpendicular to the grain of the countertop- it will slowly break itself apart. No amount of sealer or finish or paint can stop this movement and if it hasn’t happened yet, it eventually will. I’m only posting this to help out. As a carpenter, I see a lot of DIYers with broken hearts. Let me know if I posted this in error.

PS Ripping long miters on a table saw is not an an operation that can be safely performed without proper training. At the very least, tell your readers to research which side of the blade the fence should be on when mitering.

Thanks for your input Dimitri. My goal in this tutorial is not to teach people how to use a table saw. If they have one and know how to use it, they can rip at 45. If not, I mentioned some alternatives to the mitered edge. It is just showing hoe I made my countertop because I got asked so many times.

We have installed 3/4″, tongue and groove, nail it to the foor utility oak, which has knot holes, saw marks, worm holes, fissures, cracks,etc in the wood to floor pretty much the whole house ( except the entry areas, bath and utility rooms, and in front of the fire place).

My wife thought that the 27 y.o. kitchen counter tops would look awesome covered in the left over flooring. We are planning to paint the existing front trim of the counter top black, like the cabinets, and use oak bullnose, or stair nosing, to trim out the front edge of the counter surface. We will place temporary pieces of the bullnose as spacers and work from the front of the counter towards the wall.

We noticed an earlier post where you responded about the tung oil being food safe after it cures. That was great information that we would have needed to investigate. Thanks. We will let you know how it turns out.

RAY and JAN

On the subject of using Tung Oil to finish our kitchen counter tops because of its food safe properties once cured; I have subsequently found out that, since the Tung Oil comes from the nut of the Tung Nut tree; the fumes, vapor, and even mild contact with the oil in liquid, and cured states, can cause severe reactions to those with even slight NUT ALLERGIES and Sensitivities. Therefore, we will not be able to use the Tung Oil. Our daughter has Tree Nut sensitivities. Any suggestions for another food safe finish for our kitchen counter project??? Your email reply asked about pictures. Do you have a link I can send some to or up load to? Thank you.

Ray

That is good to know! Here is a great article by Fine Woodworking on food safe finish options.

http://www.finewoodworking.com/SkillsAndTechniques/SkillsAndTechniquesArticle.aspx?id=26893

There are a lot. Hope you find one that works out great for you. You can email me some pics at [email protected]. I can’t wait to see your masterpiece!

I am interested if RayJan Ritchey ended up doing this project as discussed in this comment. This is exactly how I was thinking about doing ours, but wasn’t sure how it would turn out. If possible, I’d love to see some pictures and find out how it looks.

I was thinking about using red oak flooring for a coutertop just last night. Quick dash to Home depot at 9pm to ponder, wander and desire. Would this hold up to kitchen use? What size plywood, I looked at 1/2 and 3/4″ What would you oil/stain with that would be appropriate.

Mona, I love the look of Tung oil which is food safe after it’s cured but here is an article from Fine Woodworking that lists some other options. http://www.finewoodworking.com/SkillsAndTechniques/SkillsAndTechniquesArticle.aspx?id=26893

I used 3/4″ plywood for the craft room that had a very thick veneer. That is important so if you ever have to sand your countertop down, you won’t sand through your veneer into the “not so pretty” layer of wood underneath. For a kitchen, I would use solid wood so it can be sanded over and over if need be and still last for decades.

Can the tung oil be used for a countertop in a kitchen or island? We bought an old house and are having cabinets built and want it to look old.