DIY Board and Batten Wainscoting

While focusing my efforts in the basement a couple weeks ago, I set my sights on “up-scaling” the bathroom with some visual improvements like installing board and batten wainscoting. A big thank you to Arrow Fasteners, maker of the iconic heavty duty T50 stapler.

Before

Aside from the visible ceiling guts, this bathroom was just blah. Rather than jack hammer the concrete and reconfigure the space (like I always thought I would do), I opted to use the current layout but improve the look of the bathroom.

After

Huge improvement! Right?

In my October Update, I shared a few things I did to start this bathroom remodel. 1. Removed the vanity, mirror and light. 2. Covered the hole in the ceiling with some new drywall. 3. Built an “entrance wall” in front of the shower/tub. Then I got out of the way so Bucket could do all the drywall repair in the rest of the basement.

Tools and Materials

- 1/8″ tempered hardboard

- 1/2″ mdf

- RB03 casing

- Arrow Fastener 18 gauge nailer

- 1 1/2″ nails

- Baseboard

- Crown moulding

Installing Board and Batten Wainscoting

First thing I did was bulk out the door casings to match the rest of the house. The RB03 molding is 1 inch wide at the outer edge. This is an important step since the wainscot is thicker than the thin existing door casing. Personally, I do not like the wainscoting to be proud (stick out farther than) of door or window casings.

I covered the walls with 1/8″ tempered hardboard to achieve a smooth finish. This step is faster than skim coating my heavily textured walls. I determined how high I wanted the wainscot to be. There was no mathematical equation used, I just made my eyeballs happy.

Because the hardboard is so thin and flexible, I used construction adhesive as well as nailing into the studs.

The sheets are 4×8 and some of the walls were wider than the sheets would cover without a seem. I didn’t mind a gap on the sides as it will be covered by a 2 1/2″ frame.

I did end up with one seem that couldn’t be avoided on the long wall. It would be smart to determine the location of the vertical boards before installing the hardboard so any seems would be hidden by those boards.

I didn’t do that so it was more work for me to hide that seem later with wood putty. That’s why I’m telling you to plan ahead. You’re welcome!

I ripped a bunch of 2 1/2″ strips out of a sheet of 1/2″ MDF. These are the rails and stiles that I used to create a “frame” over the hardboard. I used a laser level to project a line around the room while I attached the pieces. The MDF is rigid enough to rely solely on the nails to hold it in place. After priming, I will caulk everything which will provide additional adhesive strength as well as sealing the MDF against moisture.

The bottom rail is wider than the rest. It is installed at 8″ off the floor so that once I attach the 5 1/2″ baseboard, 2 1/2″ of rail will be showing. The wider material gives me something to nail the baseboard onto. I will come back later and install scraps at the bottom to support the bottom of the baseboard. After installing the top and bottom rails, I added 2 1/2″ stiles to complete the frame. On inside corners, I left a 1/2″ gap, so that the entire 2 1/2″ stile was visible.

After installing the top and bottom rails, I added 2 1/2″ stiles to complete the frame. On inside corners, I left a 1/2″ gap, so that the entire 2 1/2″ stile was visible.

On the outside corner, I butted one stile over the other. I applied glue to the area where the two stiles joined and nailed them in place.

Next, I installed a center rail which is 4 1/2″ wide. Visually, I like the wider width on this rail because it’s between the upper and lower (vertical) stiles. Functionally it will hold towel hooks if I decide I want to put some there.

Next, I installed a center rail which is 4 1/2″ wide. Visually, I like the wider width on this rail because it’s between the upper and lower (vertical) stiles. Functionally it will hold towel hooks if I decide I want to put some there.

I divided that wall into thirds and added stiles above and below the center rail. Again, the laser level came in handy to make sure those stiles were in perfect alignment. It looks great like this and you could paint it and be done. However, in my opinion when it comes to moulding, there can never be too much. So I wanted to cap it off with something. I cut sample pieces of 8 different mouldings before I found the perfect one. It was already primed, so didn’t add it until everything else was sanded, primed, ready for paint.

It looks great like this and you could paint it and be done. However, in my opinion when it comes to moulding, there can never be too much. So I wanted to cap it off with something. I cut sample pieces of 8 different mouldings before I found the perfect one. It was already primed, so didn’t add it until everything else was sanded, primed, ready for paint.

Prime

I used my airless sprayer to apply a coat of primer.

Fill, sand and caulk

Taking time to prep before painting makes all the difference with the final finish. Blemishes will be accentuated by the paint so take care of them now.

I used wood filler to fill in all of the nail holes and cracks.

Once that was dry, I used a power sander (connected to the dust collection vacuum) and sanded away any blemishes and imperfections I could find.

I used a hand sanding sponge to knock down all of the sharp edges. This isn’t something that “shows” but you can definitely feel the difference.

Finally time to install the topper!I added a scrap of MDF to push the moulding forward, making it appear thicker than it actually is.

Finally time to install the topper!I added a scrap of MDF to push the moulding forward, making it appear thicker than it actually is.

Topper

After trying 8 different mouldings, I ended up liking the casing I used to bulk out my door trim.

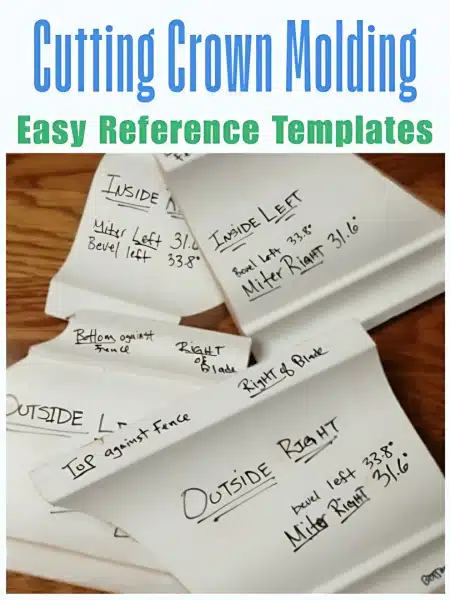

I mitered the inside and outside corners where the trim wrapped around several walls. On the pieces where they butted up to the door trim, I sanded the edges slightly rounded. Just so they weren’t blunt.

Paint

Next I sprayed everything with semi-gloss paint. In the other room, set up on sawhorses, I sprayed the baseboards too. I don’t like to paint the baseboards while in place. It kicks any bit of dirt on the floor into the baseboards which dries in the paint and makes for a VERY messy finish.

Base and Crown Moulding

After nailing the baseboards in place, I came back and filled and painted the nail holes.

I added crown moulding on the two spaces where I took the wainscot up to the ceiling. This included the tub wall enclosure wall and the vanity wall.

I wrapped the crown around the side of the tub surround wall and ended it with a nice clean return.

The application of more caulk and a little touch up paint (where needed) completed the board and batten wainscot project! I know, it’s all white! For now because I have’t installed the hooks and there are literally NO accents in the room. Even without accents, I think it’s beautiful!

Except for that tile. I wish I would have chipped it out and replaced it before I started the wainscot. I’m going to paint the grout and hope that makes my eyes a little happier. Even if it doesn’t, at this point, I’m not changing the tile. It is what it is! The rest of the bathroom is lovely! (Or soon will be.)

The next project for this bathroom is to build a vanity! I’m looking forward to that small project. I’ll get on that after I finish installing all the kitchen cabinet doors!

Love how bright & white it looks. You’re ✨AMAZING✨ What paint color did you use?

My current favorite white is Sherwin Williams Falling Snow. I change it periodically.

Looks great. I’m going to follow your steps for a project in the living room. I have read that the edges of cut mdf can suck up the paint and become rough. Some recommend filling every edge of the ripped mdf. Did you have this problem with your project? Can you share a close up picture of the edge of a batten? Thanks for the tutorial, I’m exited to get started.

I hear ya on the grout that is bothering you, cuss I have a similar issue, aside from the tile goes through my entire house in all the traffic zones. Lobbies, washrooms.

Check this for Home Improvement Ideas on a Budget .