Building Drawers for Blum Tandem Slides and Locking Mechanisms

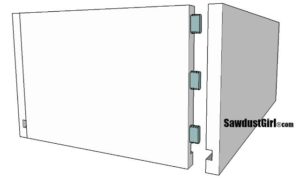

Blum installation instructions leave a lot to be desired but the hardware is great. I pretty much always use Blum Tandem plus Blumotion for my drawer slides. Once you learn how to make sense of the drawer sizing instructions, Blum drawer slides are much easier to install than side mounted drawer slides. Once your drawers are build, Installation is a breeze.

Drawer Slides

I most commonly purchase Blum Tandem plus Blumotion 563H (or 569H for heavy duty drawers). The Tandem Blumotion runners are full extension and soft close.

- The 563/569H is for 1/2″-5/8″ drawer side material. Don’t accidentally buy 563/569F which are for 3/4″ material.

- 569 has a load capacity of 150lbs. —compared to the 563s 100lbs.

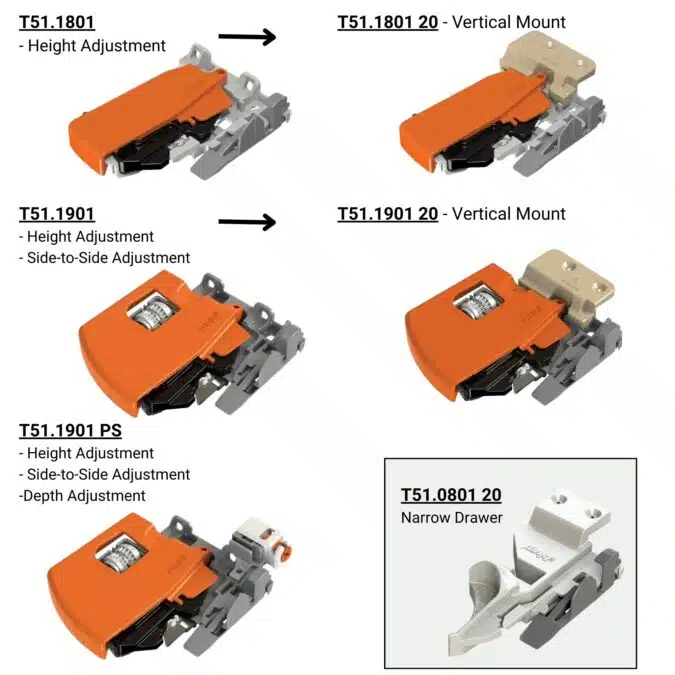

Locking Devices

You have to order a right and a left locking mechanism for each set of drawer runners. They are sometimes sold in pairs but often you have to select a R and L side—so make sure you’re going to end up 2.

There are so many options for locking devices it can be overwhelming. Blum recently added a vertical mount which has the same adjustments as it’s core mirrored device with the addition of a lip that allows for driving screws into the edge of the drawer sub front rather angled, into the backside of the sub front. I make my drawer out of prefinished plywood and imagine the vertical mount would cause splitting so I do not use these.

Here’s a rundown of the features on each mechanism for the 563/569 runners.

- T51.0801 20: vertical mount for narrow drawers – height adjustment.

- T51.1801: height adjustment

- T51.1801 20: (vertical mount)

- T51.1901: height, and side-to-side adjustments

- T51.1901 20: (vertical mount)

- T51.1901 PS: height, side-to-side, and depth adjustments)

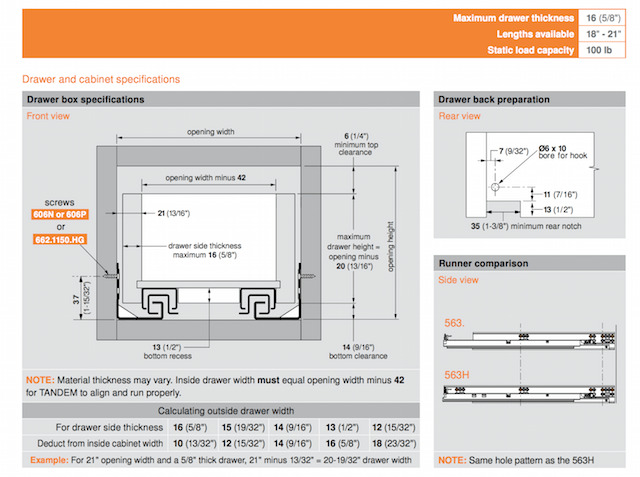

Size your drawer

- Measure your cabinet opening.

- Easy interpretation of the below Blum diagram: If you’re using 1/2″ plywood to build your drawers, subtract 5/8″ from your cabinet opening to determine the outside width of your drawer.

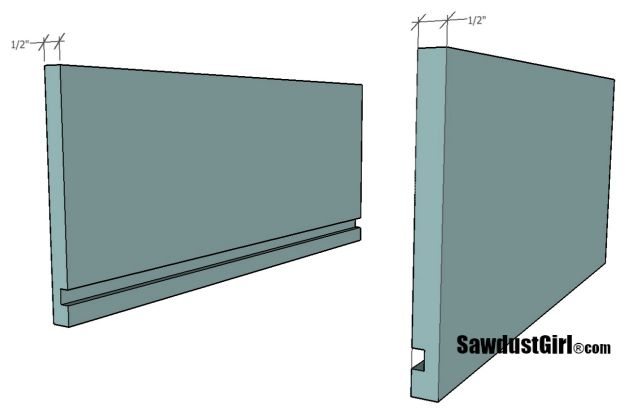

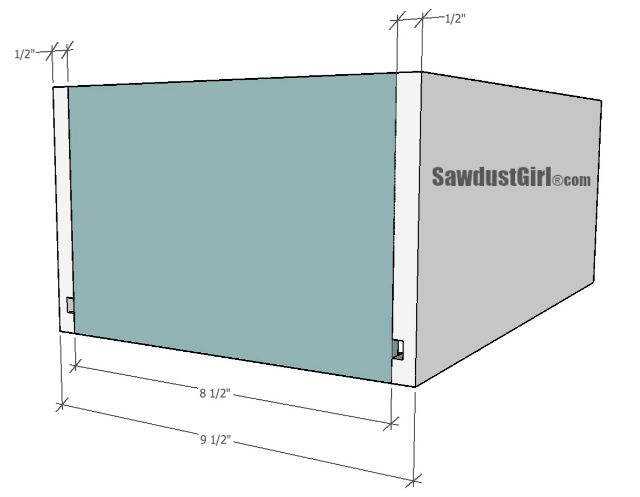

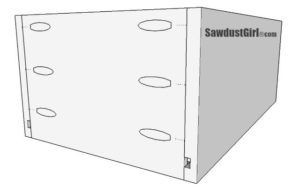

The sides should extend the full length of your drawer. The front and back should be installed INSIDE your sides. With 1/2″ plywood, the math for the width of your drawer front and back is easy — subtract 1″ from the outer width.

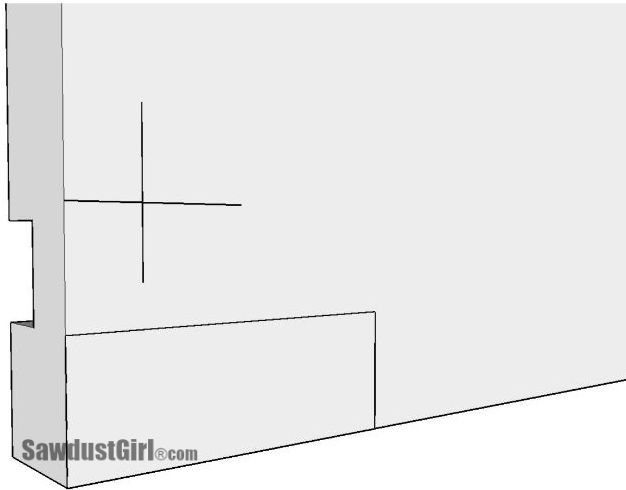

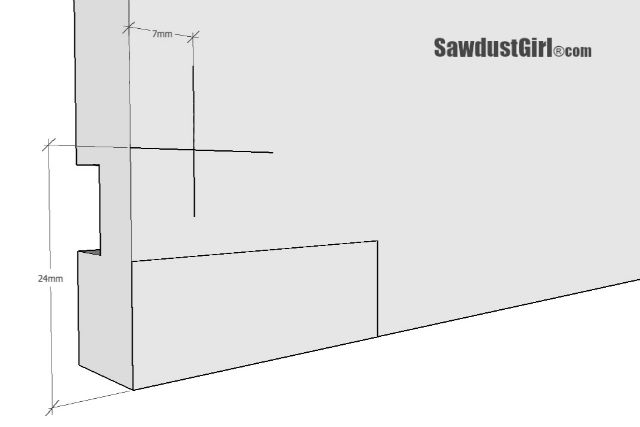

Notch and Bore Instructions

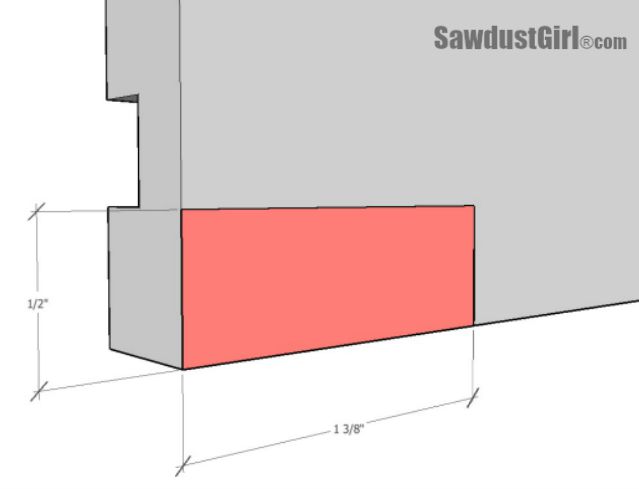

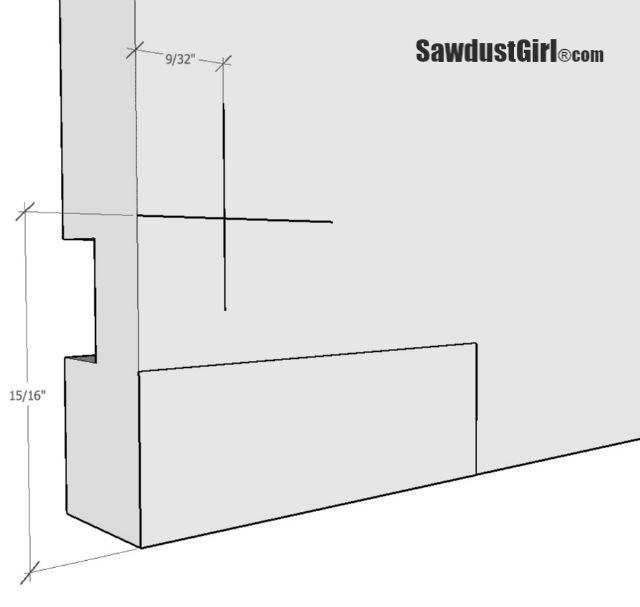

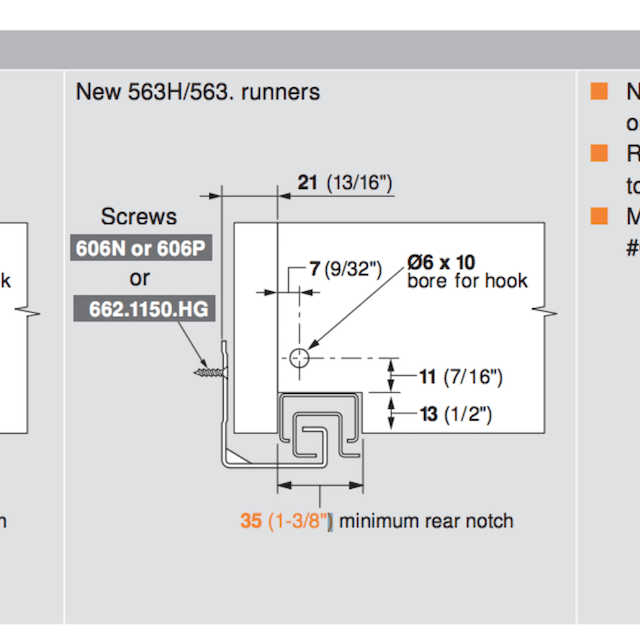

The back of the drawer needs to needs a notch and bore on both sides for the runner and hook. It’s easier to do this before assembly than after.

IMPORTANT: These measurements are specifically for the 563H/563 drawer runners.

- The bore should be 1/4″ in diameter as well as 1/4″ deep. (I’ve accidentally drilled through my 1/2″ drawer material many times —it’s barely noticeable.

- The notch you’ll need to cut out is 1/2″ tall by 1 3/8″ wide (minimum). You can cut that out with a jigsaw.

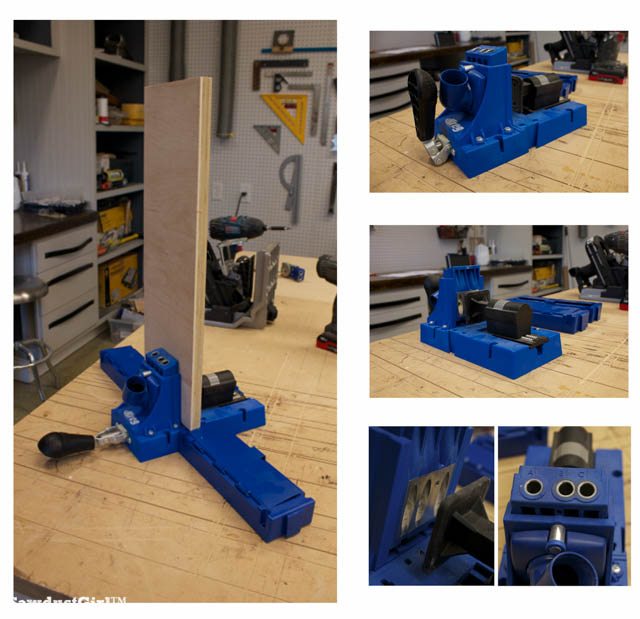

I have a tutorial for the Blum hole drilling jig I created. It holds the drawer back and allows one to drill the hole in the exactly correct location without measuring for every single hole.

Build your drawer

Using floating tenons, dowels or pocket screws. Make sure you DO NOT drill a pocket hole on or too near the groove for the drawer bottom. If you drive a screw in the groove, the drawer bottom will not slide into place.

The front and back parts can be attached to the drawer sides in a number of ways: Locking rabbet joint, loose tenons, dowels or pocket screws. Most people have a pocket hole jig so that’s what I’m using for this tutorial.

When you’re drawers are built and you’re ready to install, check out my tutorial and tips for installing drawers with Blum Tandem with Blumotion drawer slides.

I’m a woodworker- cabinet builder and Blum motion is the only draw slides I use. I buy them at EB Bradley. Just call in the order – tell them what you need and they will figure out all the components and screws needed. The other thing you forgot to mention is there is a jig you can buy to make your installation go a little smoother. You can’t overshot with the jig. Additionally, cutting the backs- I always use my dosuki and not the dado blade on my sawstop.

Fantastic … thank you!

I have been building custom cabinets and other wood projects for the last 5 years. I recently switched from Hettich to Blum drawer slides and have been too lazy to create a roadmap for install so each time I do a project I have to sit down and think through all the measurements….(I know, pretty dumb for someone who gets paid to do this!). Thanks to your post here I have been able to do that and now have some useful instructions that even my most rookie helper can follow. Can’t thank you enough for your well-laid out instuctions for the Blum….:)

I have used Blum undermount soft-close and love them too.

I agree that Blum builds great products and does a TERRIBLE job on instructions.

You have an amazing way of explaining things well–love your tutorials.

Have you worked with Tip-On Blumotion for wood drawers I am building?

If so, I would love a link to your tutorial.

I would like to know your alternative that eliminates notching the back of the drawer.