Workshop Layout — Ideas Welcome

This week I got to the point where I was finally ready to un-crate my new tools! I ordered these tools right after finishing Richwood, and moving into my new shop. I gave away my drill press, band saw, jointer and planer when I moved. The whole reason we moved was so I could have a larger workshop so I could get… more professional tools. I ordered right way because I wanted all the main tools, in hand, before deciding on the layout. Then I discovered the water issue and had to spend a couple weeks dealing with that. I picked up the tools and they’ve been sitting here for 2 weeks.

To get the shop ready to actually BE a WORKSHOP. I had to get all the non workshop crap out of there. Last week, we rented a moving truck and relocated all the stuff to a storage facility. Woohoo!

That really opened up the space — which made clear that the space is kinda gross. Even after sweeping the floors and vacuuming all the cobwebs off the walls (that I could reach).

The lower portion of the walls have some mildew/mold. I sprayed them with mold killer/inhibiter but I want to remove the stains. There’s too much surface area to try to clean it with the ZEP, as I mentioned I was going to try. I’m going to paint over it with a stain blocker. But I don’t want to paint the whole room, including the ceiling. So I’m going to go up part way, end it with a crisp line and call it an “intentional design choice”.

Planning a Workshop Layout is Hard

Back to my new tools! Finally getting to uncrate my new tools was super exciting — until it wasn’t. First, I couldn’t get the tools OFF the bottom of the crate. Second, none of these giant tools are mobile so I’m not going to easily move them once I figure out how to get them off the crates so I need to know WHERE I’m putting these tools.

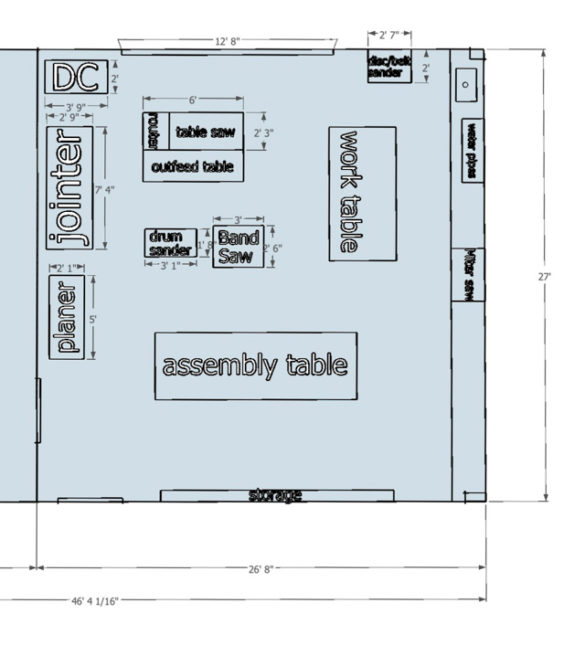

This “bay” is basically 27’x27′. I have plenty of room for all these tools and I don’t expect to love the initial layout forever. But I’d like to not immediately hate it. As in, realize that I grossly miscalculated how much space I need on both sides of my GIANT 12″ jointer. (Or something! Honestly, my last jointer was a little bench-top version.)

I haven’t had a plumber in to look a the place yet (hopefully this week) but I have access to water in here. Not sure about a drain but…I put a sink in my design anyway.

So here is my first draft of my workshop. My blog settings crunch my photos so the dimensions are hard to read. You can see (and download or print) the PDF version of this photo here. https://sawdustgirl.com/wp-content/uploads/2019/08/woodworking-tools-layout.pdf

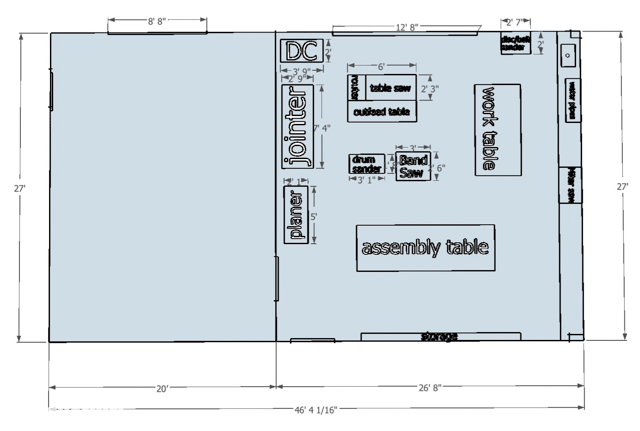

I have a whole other bay that I originally thought I’d use for a finishing room. But I’m thinking maybe I’ll pull some of that plywood off and see if I could open up that wall to make one really large workshop. I have plenty of rooms in the back that could be designated, dust free, finishing rooms. Here’s the PDF of the below photo https://sawdustgirl.com/wp-content/uploads/2019/08/both-bays-layout.pdf

So, before I get any further into this (and while I paint the lower section of the walls, I would LOVE to hear from YOU!. What you see me doing wrong, right? What am I missing, what’s not even on my radar… If you want to sketch up your idea for my best workshop setup, you can share your sketch on my facebook page or email me. Thank you in advance for you HELP! Who knew this would be so daunting? But still exciting.

Thanks for the link to the curtains! I worked in a professional wood shop for a while, getting items into and out of the finishing room was always nerve-wracking. Something like these makes that easy, plus you can use the space for other things when finishing isn’t the job of the day!

Sandra,

Agree with just about everything I have read but have one question. If you tear down the wall between work spaces are the doorways large enough for moving items to a back finishing space?

Maureen

Good question! I need to look at that.

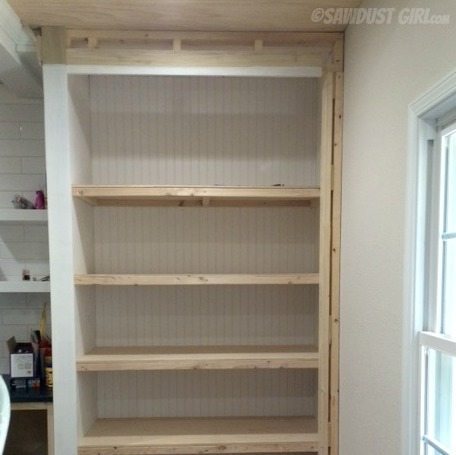

You will really regret it if you don’t take the chance while the room is basically empty to paint the walls, ceiling and epoxy the floor. My only other suggestion is to do one entire wall of peg board so you can hang all of your smaller tools and gadgets.

Practically empty? LOL Everything is IN there, it’s just not put away. But I see what you’re saying and agree. Painting now.

You have some great comments, but my biggest concern was regarding clearance. It’s hard to tell from the photo, but I specifically wondered about clearance around the table saw. Can’t wait to see what you come up with.

Also, I echo the comments about painting everything a high gloss white. It’ll brighten that space right up. With no natural lighting, it will make such a big difference.

I planned about 3′ between everything. Might be too much if I don’t want to have to take steps from one machine to another. It’s so difficult to plan this out on paper! 🙂

Couple of thoughts:

We put everything we could on mobile bases. You can bet you’ll be making changes down the road, whether you get new tools, change your work flow, whatever. Even you work, assembly tables should be on casters. We had a local welding shop make bases we designed and they work great!

You may think you have everything you need now, but you’ll probably buy more tools over time so the more space the better. If you can take out the wall between your spaces, go for it.

We found a sink was useful, but we use it most often when we’re finishing. You might considering locating a sink in or near your finishing area.

It looks like you planr and jointer are a little too close together for outfeed purposes. If they’re not on mobile bases, you might want to space them out a bit more. Same for your table saw. You’ll want enough space around your saw to rip a full sheet and your design looks a bit tight.

THink about using mobile racks for hand tools, drills, clamps, fasteners, etc. Saves time, steps and frustration.

Finally realize even the best layout will evolve over time. ENjoy the process and congrats!

Lots of really great input! Ordered mobile bases. I agree about wanting a sink IN the finishing room. And definitely going to be building some mobile storage for clamps and such!