Workshop Layout — Ideas Welcome

This week I got to the point where I was finally ready to un-crate my new tools! I ordered these tools right after finishing Richwood, and moving into my new shop. I gave away my drill press, band saw, jointer and planer when I moved. The whole reason we moved was so I could have a larger workshop so I could get… more professional tools. I ordered right way because I wanted all the main tools, in hand, before deciding on the layout. Then I discovered the water issue and had to spend a couple weeks dealing with that. I picked up the tools and they’ve been sitting here for 2 weeks.

To get the shop ready to actually BE a WORKSHOP. I had to get all the non workshop crap out of there. Last week, we rented a moving truck and relocated all the stuff to a storage facility. Woohoo!

That really opened up the space — which made clear that the space is kinda gross. Even after sweeping the floors and vacuuming all the cobwebs off the walls (that I could reach).

The lower portion of the walls have some mildew/mold. I sprayed them with mold killer/inhibiter but I want to remove the stains. There’s too much surface area to try to clean it with the ZEP, as I mentioned I was going to try. I’m going to paint over it with a stain blocker. But I don’t want to paint the whole room, including the ceiling. So I’m going to go up part way, end it with a crisp line and call it an “intentional design choice”.

Planning a Workshop Layout is Hard

Back to my new tools! Finally getting to uncrate my new tools was super exciting — until it wasn’t. First, I couldn’t get the tools OFF the bottom of the crate. Second, none of these giant tools are mobile so I’m not going to easily move them once I figure out how to get them off the crates so I need to know WHERE I’m putting these tools.

This “bay” is basically 27’x27′. I have plenty of room for all these tools and I don’t expect to love the initial layout forever. But I’d like to not immediately hate it. As in, realize that I grossly miscalculated how much space I need on both sides of my GIANT 12″ jointer. (Or something! Honestly, my last jointer was a little bench-top version.)

I haven’t had a plumber in to look a the place yet (hopefully this week) but I have access to water in here. Not sure about a drain but…I put a sink in my design anyway.

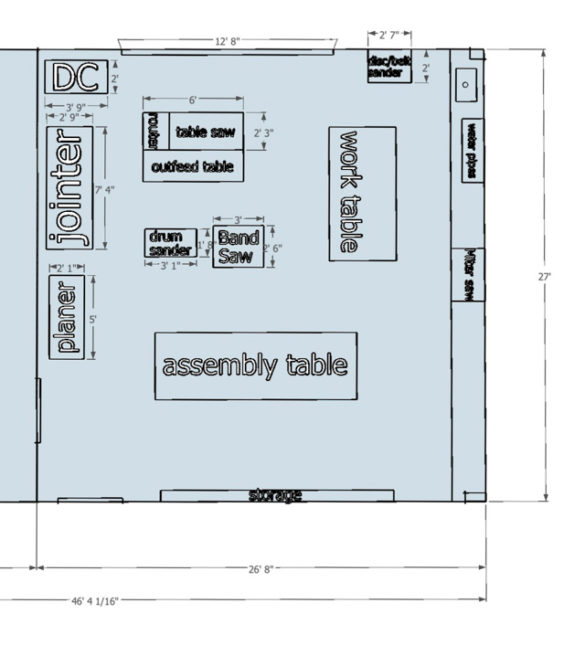

So here is my first draft of my workshop. My blog settings crunch my photos so the dimensions are hard to read. You can see (and download or print) the PDF version of this photo here. https://sawdustgirl.com/wp-content/uploads/2019/08/woodworking-tools-layout.pdf

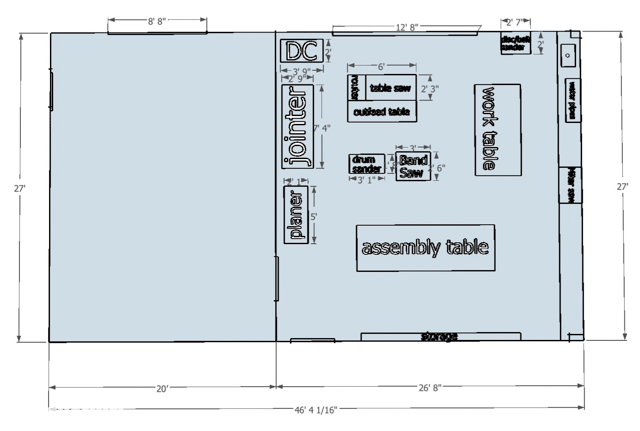

I have a whole other bay that I originally thought I’d use for a finishing room. But I’m thinking maybe I’ll pull some of that plywood off and see if I could open up that wall to make one really large workshop. I have plenty of rooms in the back that could be designated, dust free, finishing rooms. Here’s the PDF of the below photo https://sawdustgirl.com/wp-content/uploads/2019/08/both-bays-layout.pdf

So, before I get any further into this (and while I paint the lower section of the walls, I would LOVE to hear from YOU!. What you see me doing wrong, right? What am I missing, what’s not even on my radar… If you want to sketch up your idea for my best workshop setup, you can share your sketch on my facebook page or email me. Thank you in advance for you HELP! Who knew this would be so daunting? But still exciting.

I would go into the space and layout some boxes and sheet good to represent your layout. It would good if some this could be the same height as the tables and machines. Then I would walk through some projects that you have done. Do the actual bending, stooping, swinging, etc of materials. Do you notice that your butt will run into something? not allow someone to pass? will that 8′ sheet or plank need support as you guide it through a cut on the band saw? table saw? etc. These might not be the right scenarios for you, but role play the fabrication os a tall cabinet, a side chair, a coffee table, a box, an automata, etc. Move the stage set around until you feel it is right.

just a thought.

First recommendation: Paint. Paint every wall and the ceiling. Do it twice. Use high gloss paint. It will dull over time with age and dust but until then will give you maximum working light from each watt of illumination. Second recommendation. Shelves. Lots of shelves. They will never be easier to install than now, you have lots of room to move ladders around and they will be used! My shelves have three coats of gloss latex paint and, contrary to my fears, make for easy sliding of boxes and tools. Third recommendation: Panel at least one wall with plywood. I have half-inch plywood in my shop and 3/4 inch in the attached garage. The 3/4 inch is better. Fourth recommendation: if it gets hot or cold where you live and you plan to work during those times, install an excellent heating and cooling system. I started out with a vented kerosene stove, upgraded to a direct-vent Toyo space heater but now have a far superior mini-split air-conditioning system. It is marvelous in summer and winter, very quiet, and very efficient. Highly recommended and you can do much of the installation yourself. Fifth recommendation: Put on a floor coating. Grey is easily available, so is beige, but if II were doing it again I would apply white instead of grey. Note, I have floor coating only in my two garages. I wasn’t foresightful enough to do the shop area before it became covered with machinery and work benches. Sixth recommendation: Get plenty of 120 and 240 outlets. I also have a few coming down from the ceiling. Seventh recommendation: Read shop design books.. A few: Great Workshops from Fine Woodworking, 2008; The Workshop, Scott Gibson 2003; The Workshop Book, Scott Landis 1981; Great Workshops from Fine Woodworking, 2008; How to Build a Great Home Workshop, Peter J. Stephano, ed. 2007; Best Workshops, Fine Woodworking, 2013; How to design and Build Your Ideal Workshop, 1998 Bill Stankus. Last recommendation: give early thought to eventually having a permanent installed dust collection system. I have a 3 HP Oneida central system in one corner with ducting running to each major machine. If given a second try, I would put the noisy cyclone cleaner outside the shop and avoid much noise plus I wouldn’t need expensive filters.

Painting now. I have a good DC (It’s labeled DC on my layout but I think most people don’t see it). Have plenty of power so I can have a 220 wherever needed. I definitely need to get an AC installed ASAP. It’s SO hot in here. Thanks for the book recommendations, I’m ordering a couple now.

When my Dad built his dream work shop he made sure each tool got a dust pick up duct (I don’t know the official word), copper pipe all around so there was compressed air hook-ups everywhere, and lots and lots of plug-ins. Since he passed away, I’ve been using it some and my only struggle is that he added a planner which is in a tight spot and doesn’t have enough clearance for long boards and it’s in the way of the 8′ sheet metal break, so you can’t put big pieces all the way in it. So, my take away to share is: more clearance is better! 🙂 Good luck!

What about dust collection? More and better lighting? Air compressor plumbing? The casters are a great idea I’m a senior and couldn’t work without them!

When my dad’s health started to decline, he purchased and attached heavy duty locking casters, appropriate to each tool, therefore allowing him to move things around with ease. His giant metal lathe even got its own custom rolling cart built to handle the weight. Every tool cabinet was nested into its own dolly as well. Any of us could unlock the wheels and move things if needed. Even he was able to still move stuff around as he puttered in the shop, just weeks before he died.