Cabinet Hardware Installation Jig

There are a lot of cabinet hardware jigs out there and I’ve used quite a few. Most of them work fine for standard 3″ – 5″ pulls but are useless when you’re using really long drawer pulls – like I used on my linen cabinet. I found the True Position Cabinet Hardware Jig a couple years ago and it’s made hardware installation so much easier. I have since seen tons similar looking jigs around the web that are way cheaper. They all seem to function as this one does so I assume this review/tutorial will work for most.

Cabinet Hardware Installation Jig – Core Unit

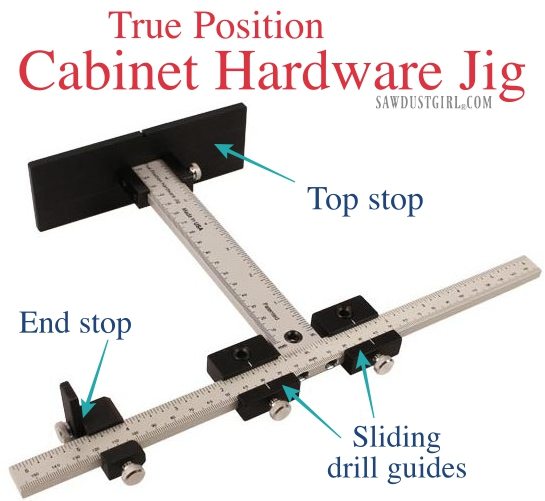

- The rulers have both standard and metric readings which is helpful when the pulls give only metric numbers for hole spacing.

- The core unit includes: T-Square with center bushing, two sliding drill guides, one sliding end stop, and a 5mm drill bit. (All in a cardboard case w/ handle.)

- With the core unit, you can center the jig on any drawer front up to 16″ in width.

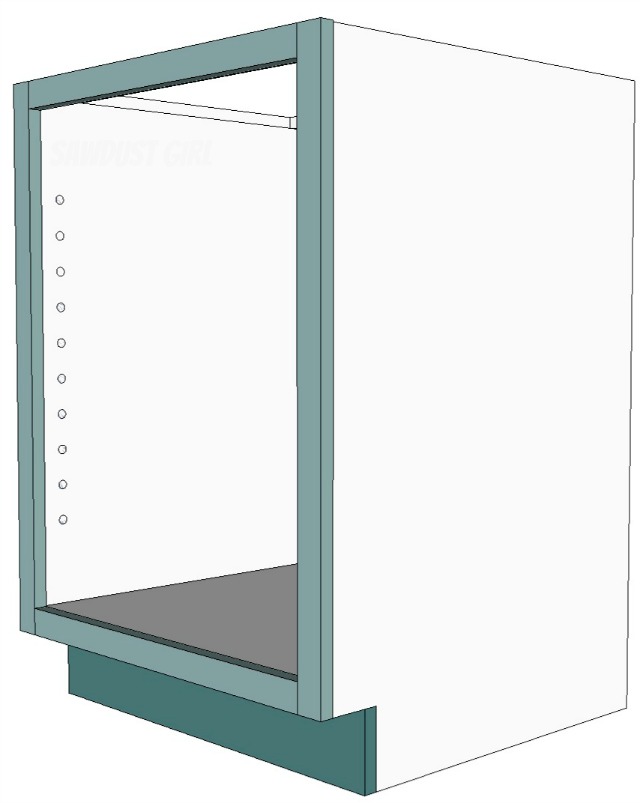

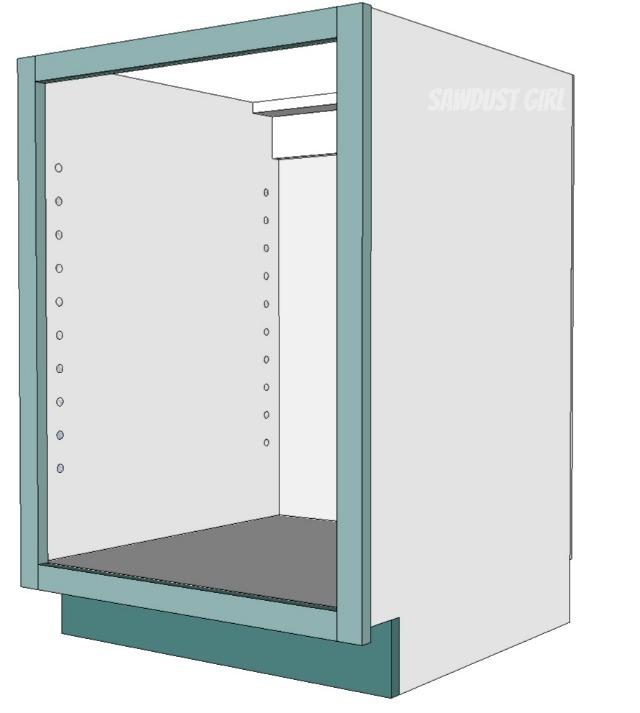

Shelf Pin Drilling Jig

- You can purchase extensions that extend the width to 30″.

- In addition to giving you more cabinet hardware drilling possibilities, the extensions turn the cabinet hardware jig into a shelf pin drilling jig.

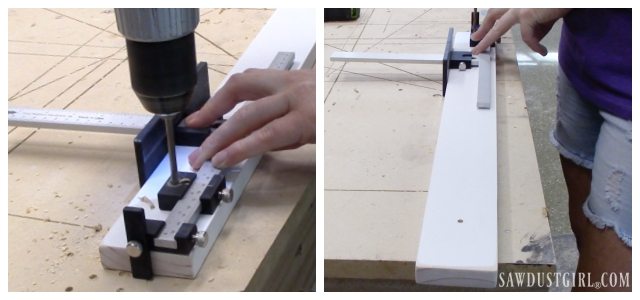

How to use it

There are multiple ways to use the jig, with and without the extensions.

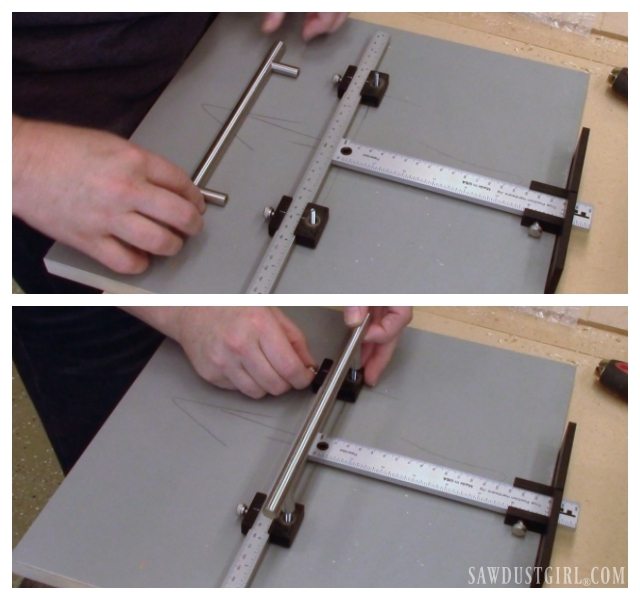

1: Measure and mark the center (width) on every drawer front.

Lock the sliding drill guides in place so once you find your mark (in the center bushing), you’re ready to drill. This works great when you’re using the same hardware for multiple drawer fronts that are different sizes.

2: Use one sliding drill guide with the end stop and one extension arm.

Position the sliding drill guide where needed on the side with the stop. Center one of the many holes on the extension arm where needed and then lock in the extension nut so it tape off the other holes near by — so I don’t accidentally drill the wrong one. This is useful for really wide drawer fronts where you’re installing knobs near the outside like I did with my craft room Map Drawers.

I used basically this same method for my linen cabinet door hardware. I used the center bushing and one hole in an extension arm.

3. Another option for the same “wide drawer front” situation is to use one drill guide with the end stop. Drill the hole on one side of the drawer front. Then flip the jig over and use on the opposite side.

4. This method uses both extensions and a special stop that I whipped up in my workshop. I like this method over option two where the T-square is positioned near one side of a wide drawer front. Because this allows the T-square to be more centered on the drawer front, it feels more stable.

Edit: True Position now offers a Long Pull & Rapid Center accessory kit for $129 that would replace the need for this DIY stop I created. I will probably just keep using my little plywood block.

With my special stop, I can set up the jig and quickly drill multiple drawer fronts without having to measure each drawer front to find center. I used a T-track bolt and knob to secure my scrap wood L “stop” to the jig.

The shop made stop can be positioned anywhere on the extension arms, making this method the most effective and stable. Boom!

Without the stop, if you use both extensions, you still have to measure to find center on all drawer fronts. That is wasted time, in my opinion. NOT wasting time or dealing with “fiddle factor” is the whole purpose of a very expensive jig like this. The simple addition of the “extension arm stop” takes care of that problem.

I use my jig all the time. I may try finding a cheaper option for an extension and quick centering accessory True Position now offers.

I do have a complaint with this jig – the “Large Stop” is not wide enough. When the extension arms are attached it is really easy for the jig to rock resulting in slightly misaligned holes. I find I need to clamp the ends of the extensions to the wide drawer fronts (or doors) to prevent this and that extra step is a lot of wasted time.

I have looked at as many of the similar jigs and every one of them has the same sized Large Stop so I haven’t bothered purchasing a different jig “base”. If ever I find one I’m going to buy it — because that would make this whole set up practically perfect.