How to Remove Rust from Steel Top Tools

Today I’m showing you how to remove rust from tools. One way to do it anyway. The other day I took some time to clean my table saw. I asked my Instagram community about their cleaning rituals– and there were a lot of products I’d never heard of. Check out that post if you want to see all the other suggested products. The vast majority of commenters use WD-40 and a metal brush or steel wool. That’s what I use. It’s cheap, readily available, and effective.

How to Remove Rust from Tools

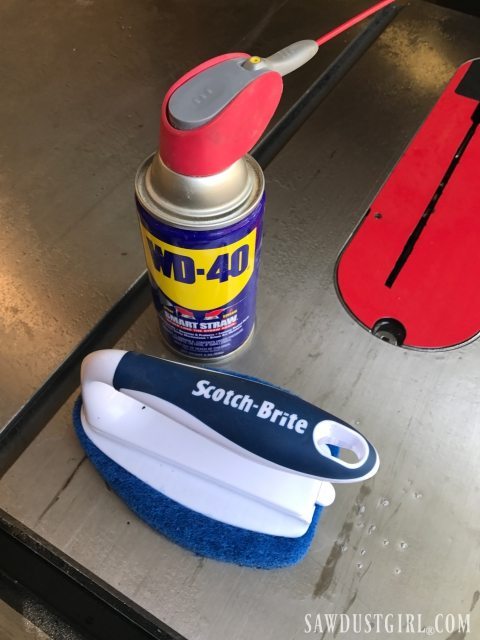

Needed:

- WD-40

- 00 steel wool or an abrasive pad

It doesn’t take as much elbow grease if you let the oil sit longer. Just don’t let it sit so long that it dries. Find the happy medium. If you have other tasks to complete while the oil sits, great. If not, it’s like waiting for water to boil. You just want the rust to dissolve and move on. So you can get to work doing the thing you wanted to do with that rusted power tool! I have included the patient method and the

Time and Elbow Greese

- saturate steel top tools with WD-40

- let it sit for about 10 to 30 minutes

- scrub the abrasive pad or steel wool

Then wipe with paper towels and repeat.

Depending on how bad the rusted area is, you may need to let the oil sit longer. Or you can use a power sander. I was able to get my table saw smooth to the touch by scrubbing by hand. However, there were still some visible blemishes that I wanted to remove. I don’t have the patience to let the WD-40 sit for more than 30 minutes so I brought in a power sander. Protecting the blade insert from the power sander is a good idea. Remove that puppy.

Power cleaning

My random orbital sander made quick work of getting rid of the remaining rust spots. I applied more WD-40 and used 600 grit sandpaper on medium speed. A shop apron is a good idea if you’re using a power sander. The sander tends to splatter a bit of dirty oil at you.

Coat and protect

The final step is to coat your freshly cleaned steel top tools with T-9, a waterproof lubricant. Let that dry, then buff. An alternative to T-9 is Renasainse Wax. Either can be recoated frequently.

Keeping metal tools polished helps material slide easily as well helping the tool stay clean and rust free.

This technique would certainly remove rust from other power tools, hand tools, and woodworking tools and bits too. Let the rusted tools soak in a plastic container with WD-40. Then scrub with a wire brush and wipe with paper towels.

My table saw looks practically new again after dedicating an hour to cleaning and polishing. If I polished it weekly it would take 10 minutes and wouldn’t get so bad that it would again require an hour. Tools are pretty big monetary investments. It’s a good idea to take good care of them to help them last longer and work better!

Want to see why I no longer use my table saw blade guard? Watch this!

Additional workshop projects you might like:

Thank you for Pinning and sharing!

WD-40 is hazardous to breath and touch, make sure to use adequate ventilation and protective gloves. Read MSDS for more information.

I have been using WD-40 on my table saw top for 25 years. I spray WD-40 all over the top and then cover with a heavy trash bag working out all the air bubbles. Then cover with a blanket and plywood on top. I have no rust and when it is time to use the saw again, I just clean with solvent. Very humid here in Houston.

I have heard that WD-40, or other wet sprays can actually get into the wood, which isn’t good. I give all my tools a good wipe down, then put a couple of coats of paste wax on the tops. After that I spray the tops with a dry lubricant. Not saying it’sa a better idea, just telling you what I do. I do this for my lathe, band saw, scroll saw and table saw. No matter what method you use, a slick and shiny table is a joy to use. I also wax my rip fence.

I definitely wouldn’t just use the WD-40 and leave it at that. I use T-9 or Renaissance wax for the final steps. You might have missed that in the post.

Any ideas for wrenches, screwdrivers, pliers etc……

I assume the same method would work. Just wouldn’t be able to use a sander. A steel brush would work.

Looks like new! I find that periodically polishing keeps the rust at bay. Though, not a lot of humidity here in Colorado so that might be why also. Thanks for sharing the tip!

Even without humidity, your steel top tools probably need a good cleaning or at least waxing periodically. Depending on what you cut. I can’t tell you how much I hate when Pine leaves steaks of sticky sap on my sawtop.