How to Make a Dado Jig for Palm Router

Want to learn how to make a simple dado jig? Hey Sawdust Girl Readers! Happy New Year! It’s SG Squad member, Timisha here from ToolBox Divas. It has been a while since we last chatted. The holidays are a great time to spend with family and unwind. I can honestly say I did absolutely NOTHING. And I ate EVERYTHING. ![]() But now that the holidays are over, its time for a diet and it is time to get back on track and get back into the workshop. So this month we are working on jigs. The squad was tasked with coming up with woodworking jigs we could use in our shop. I decided to develop a jig for my palm router. I have a larger router and a router table. However, it’s a huge hassle to get it all set up and change out the bits. So I like using my palm router when possible. Problem is, it’s a bit of a challenge keeping the cuts straight and creating dado slots. I want to be able to do more dado joinery in future builds. So in this post, I am going to show you how I developed a simple jig for cutting dados with my trim router.

But now that the holidays are over, its time for a diet and it is time to get back on track and get back into the workshop. So this month we are working on jigs. The squad was tasked with coming up with woodworking jigs we could use in our shop. I decided to develop a jig for my palm router. I have a larger router and a router table. However, it’s a huge hassle to get it all set up and change out the bits. So I like using my palm router when possible. Problem is, it’s a bit of a challenge keeping the cuts straight and creating dado slots. I want to be able to do more dado joinery in future builds. So in this post, I am going to show you how I developed a simple jig for cutting dados with my trim router.

How to Make a Dado Jig for Palm Router

Materials

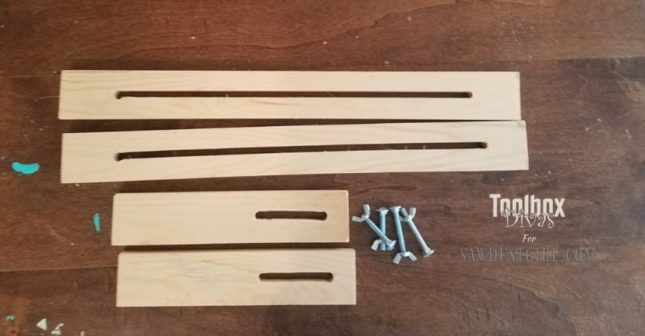

- 1 – 1x3x6 Square edge Premium Board

- 4 – 2” ¼ Carriage bolts

- 4 – ¼ Wingnuts

- 4 – 1 ¼ screws

Cut List

- 2 – 24”

- 2 – 12”

I wanted to make a jig that would be flexible and handle boards of various widths and thickness. I also wanted to use what I had on hand. When I think of a shop jig it should be something made using material that is easily accessible and it shouldn’t be too complicated. OK, Let’s Get Dirty!

The Process

- I started by cutting the 1×3 to size. Then using a ruler I marked a line down the middle of the boards for the slots. Here is a quick tip to check if you marked a straight line: Using a laser level, like this Bosch Self-Leveling Cross-Line Laser Level, place it at the head of the board and on a flat surface. If the laser lines up with the line, it is straight.

- Drill a hole into the board with a drill bit that is wider than the router bit you’ll be using to make the slot. I used a ½” drill bit. The router bit that I used to make the slots was a ⅜ inch straight bit.

Using the router cut the slots for the bolt to pass through on the boards. To create the slots I initially I tried making use of a couple of tips I saw online for the easiest way to create a routed slot. One way was to take a drill press and to drill all the way down the line that you want to route and then you go back in and clean it up with the router. Let me just say, I hated that process, so I scrapped it.

Using the router cut the slots for the bolt to pass through on the boards. To create the slots I initially I tried making use of a couple of tips I saw online for the easiest way to create a routed slot. One way was to take a drill press and to drill all the way down the line that you want to route and then you go back in and clean it up with the router. Let me just say, I hated that process, so I scrapped it.

Then I had a genius idea that I would just drill 2 holes at either ends of the slot would be and I’d route from one end to the next with the palm router to create the slot for the bolts.

Then I had a genius idea that I would just drill 2 holes at either ends of the slot would be and I’d route from one end to the next with the palm router to create the slot for the bolts.

This was the result. It was a total disaster. Even with a board as a fence, my hands are just not steady and for some reason, my fence wasn’t that great either. Needless to say at the end of the day, I had to actually break out the router table to create the slots. I know the objective of this task was to reduce having to break out the router table. But in order to create the jig to create dados my palm router wasn’t going to cut it, at least not yet. The slots were created with ease using the router table.

This was the result. It was a total disaster. Even with a board as a fence, my hands are just not steady and for some reason, my fence wasn’t that great either. Needless to say at the end of the day, I had to actually break out the router table to create the slots. I know the objective of this task was to reduce having to break out the router table. But in order to create the jig to create dados my palm router wasn’t going to cut it, at least not yet. The slots were created with ease using the router table.

I set up the router table and insert the bit into the opening that I had drilled with the drill press and I cut open the slot. When working with a small piece of wood like this, I highly recommend using an item like a Featherpro so that it reduces the kickback from the wood and the wood actually stays down while you’re running it through the router. You want your slot to be as smooth and as straight as possible. This is important so that you can run your bolt up and down the slot tightening the jig for different size material. For the two 24in boards I ran a slot down almost the entire length of the board. For the 12in. boards, I ran the slot down about ⅓ of the.

4. Route a ledge for the palm router to sit on on the two 24in. boards. I should also note that this jig I am making is specifically geared towards the Ryobi palm sander. When creating your jig customize it to your palm router to ensure that the measurements are geared toward the bottom guard of your palm sander.

4. Route a ledge for the palm router to sit on on the two 24in. boards. I should also note that this jig I am making is specifically geared towards the Ryobi palm sander. When creating your jig customize it to your palm router to ensure that the measurements are geared toward the bottom guard of your palm sander.

5. Assemble the jig. Once everything was cut it was time to start assembling the jig. Using a speed square I lined up one of the 24-inch boards with the 12-inch boards placing the 24-inch board on top of the 12-inch board. Before screwing in the screws I went ahead and drilled holes where the screws would go to reduce the likelihood of the board splitting.

Then I realized once I had all of my boards and everything in place I have no way of placing the router into the crevice of the jig. So I went back and cut an opening into the 2 12in. boards using my jigsaw. I cut a little opening to match the largest bit that I would probably use to create dados, which is a 3/4 inch router bit.

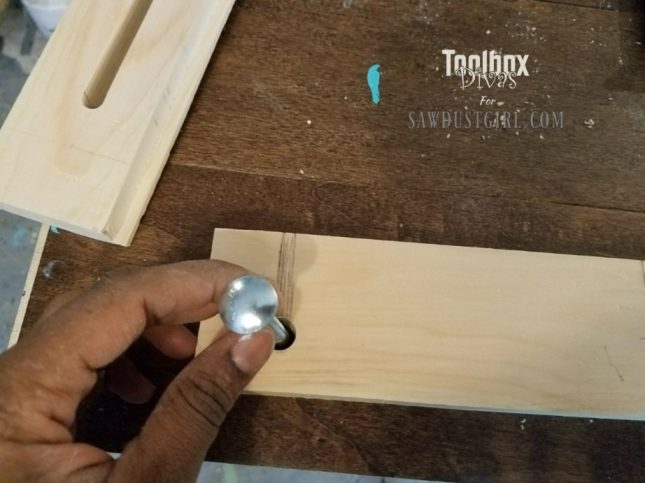

I drilled a hole into the second 12-inch board for the bolt to fit into. I then uncovered another area where I needed to make some changes. In order for the jig to sit flat on the workbench the bolts needed to be recessed into the wood. So using the drill press again and a forstner bit that was 3/4in., I drilled a hole further into the wood so that the bolt head would rest flat into the 1×3. Then I went back on the bottom side of boards with a larger router bit about 1/2 the depth of the board to create recessed slots. Now the bolts could move up and down the boards flush with the boards in the slots.

6. Clamp the jig and the board to the workstation and tighten to fit your router and wood.

With everything lined up, it was time to put this jig to use and to see if it works. I clamped it to my workbench making sure that everything was square. Making sure that the workpiece I was using was also clamped to the workbench. I tested it using a scrap piece of 3/4″ and 3/4″ router bit to create a dado.

I absolutely love these Bosch laser depth router bits. The cuts were so clean and seamless. There was very little to no tear out of the wood and the best thing is — it worked.

The problem was I assumed that the plywood that I was using was actually 3/4 in. So my dado joint wasn’t the tightest. So in that instance, I learned never to assume that you actually know the width of the piece of wood that you’re working with. Always measure it, so that you can create the perfect dado joint. An ideal dado joint is about 1/4in. depth of the material and when you place the material into the dado opening it should fit nice and snug. Luckily this was just a test piece of wood.

In my project, I’m actually working with MDF and the material thickness is 1/4in. Before I got started, I did double check the thickness and I used a 1/4 inch router bit. And you guys we had success. Again I really have to give credit to those Bosch router bits. Not only did it cut plywood very well, nice and clean; it cut this MDF flawlessly. This was my first time working with MDF. I wanted to sample it and test it out a little bit to see how the properties of MDF differ from plywood and from pine. So this was a bit of an experiment for me with both using a palm router to create dados and with using MDF. I love how it all turned out. I will definitely use my palm router again in the future to make dado cuts.

If I do this again, I probably would not create so many moving elements of the jig. I only had one area that was a straight 90-degree angle everything else moved, which meant that I had more flexibility. However, it also meant that I had more areas that I had to square up. So set up of my jig takes a little longer than I would have liked, but its nothing compared to the time it takes to pull out my router table. I will probably tweak this jig a little more as I go along in the future. However, it’s a really great simple solution to creating dados for dado joinery. And I would love it if you have any tips or any feedback that would aid in future enhancements for this jig.

Check out what I created using the new dado jig. It’s Every Girl’s Dream Jewelry Dresser. Alright Guys, Till next time. ~T.

I like to use flush trim bits to cut dados. Form the template from two straight pieces spaced apart using the actual material for which you need the dado. For larger dados where you don’t have the exact size bit, used a smaller size, the spacing of the rails determines the width, not the bit.

Donald its funny as I as using it I wondered the exact same thing LOL. But then I remembered why I only fixed one side. I had varying sized projects I needed to work on that required I use the router in two different ways.