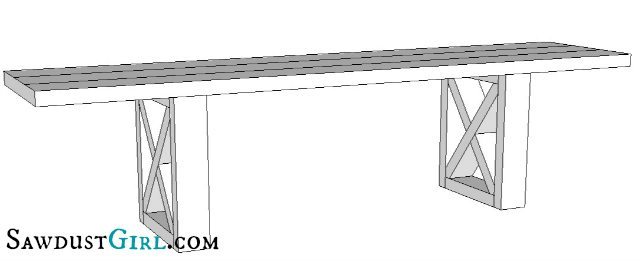

$20 X Leg Bench Woodworking Plans

This super easy X Leg Bench can be made for about $20 in only a couple hours. All you need is some good 2x material, a miter saw and a drill. This DIY Build Plan utilized simple joinery and inexpensive materials. It’s a great project to use as a jumping off point if you’re new to furniture making and woodworking. This post is sponsored by 3MDIY.

How to build an X Leg Bench

Materials for one X Leg Bench:

- Three 6′ 2×6

- Two 8′ 2×4’s

- 3″ long wood screws

- 2 1/2″ wood screws and washers

- Miter saw

- drill

- safety gear

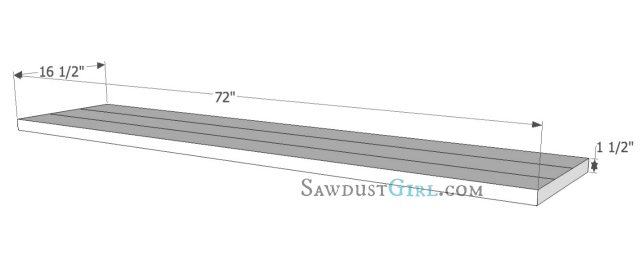

1. Bench Top

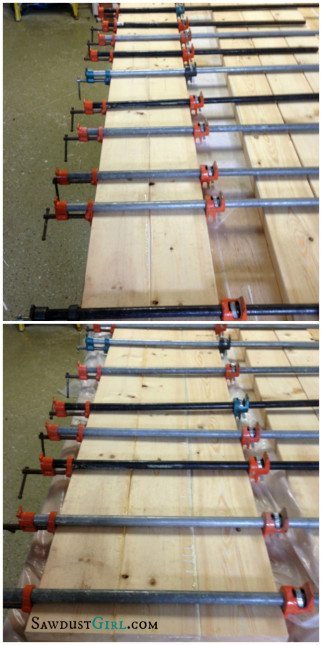

The first thing to do is glue up the benchtop which is made up of three 6′ long 2×6’s. Slather your wood glue on both ends being joined and use LOTS of clamps.

I glued up two 2×6 planks and let that set up and then added the next piece. It’s difficult to glue up too many pieces at one time without things slipping and sliding and buckling.

Finished bench top is 16 1/2″ wide.

While the glue on your bench top is setting up you can work on your legs.

When you cut all your parts, make sure you are wearing proper safety gear– please! I’ve been doing this long enough to have had some close calls and been thankful I had my safety glasses on so I do NOT take chances with safety. Eyes, ears and lungs — ladies and gentlemen. Don’t argue- just do it!

Safety gear is super important!

- Safety glasses

- Dust mask for sawdust (you know there are different ones for painting, right?)

- Ear protection

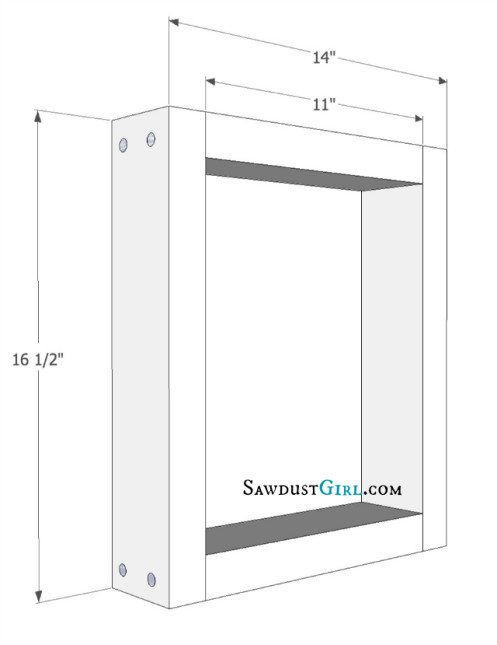

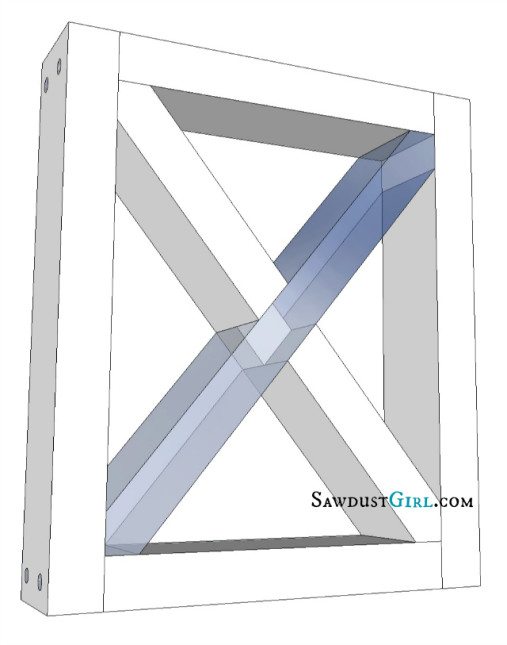

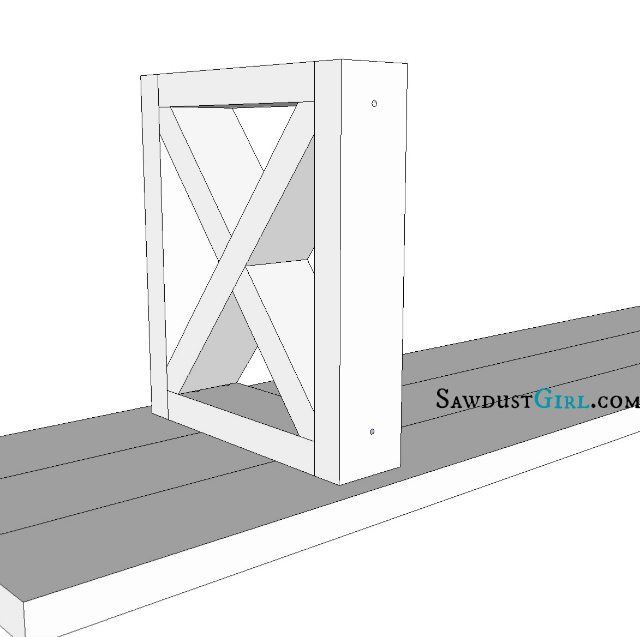

2. Leg frames

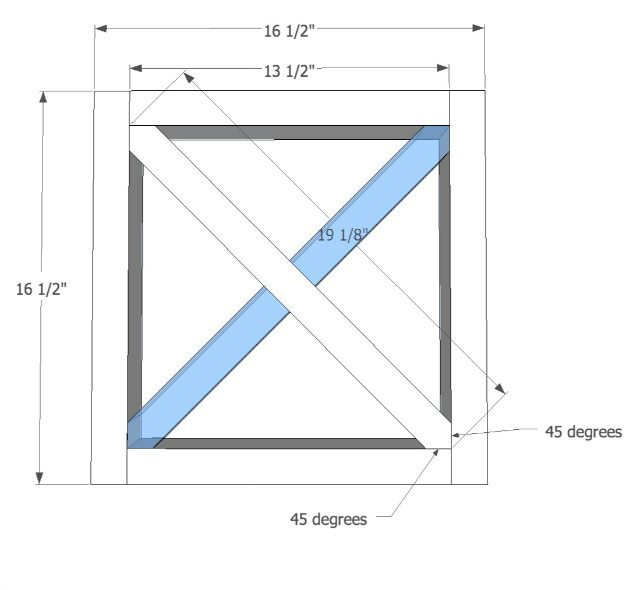

The leg frames (the X will go inside this frame) are made up of 2×4’s cut at 16 1/2″ and 11″. 2 of each for each leg.

I assemble the leg frames with glue and 3″ #10 wood screws using a corner clamp to ensure the corners were square while I drove in the screws.

3. Cut your X braces

- 4 — 18″ 2×4 pieces

For the X’s. Cut your X pieces at 18″ long and then cut the angles. The easiest way to find the angles is to place a 2×4 behind the frame with the centerline marked so you can line that up with the corners. Then draw lines where you need to cut.

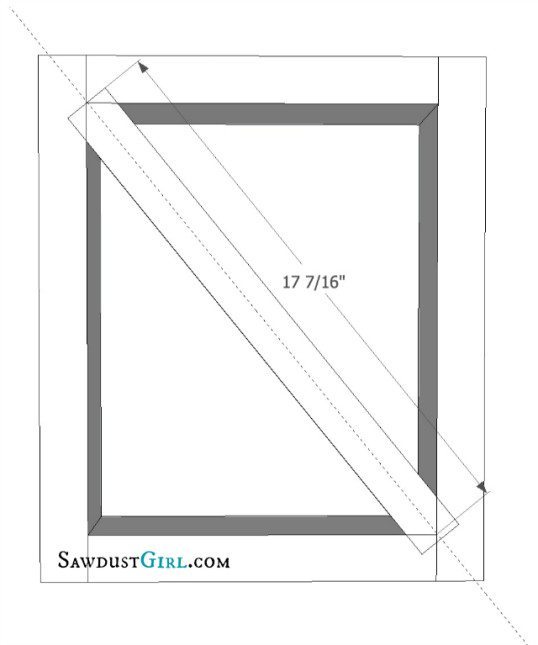

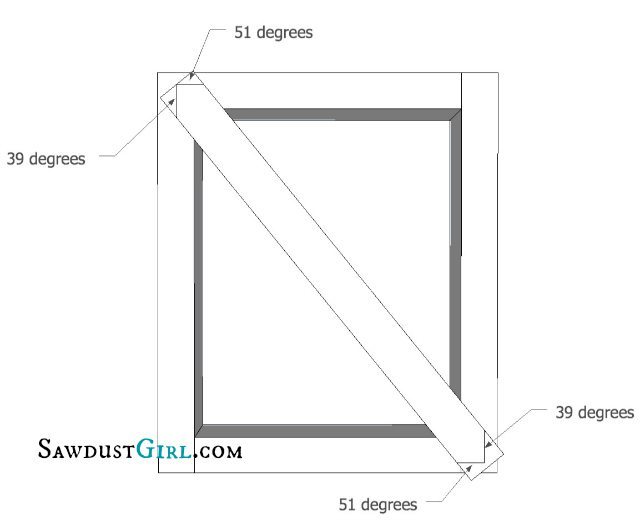

The centerline of the X 2×4 is 17 7/16″ long. The angles for this specific leg are 39 degrees and 51 degrees. If your saw doesn’t cut past a 45 degree angle you’ll have to widen your leg.

Alternate leg for those whose saws don’t cut a miter past 45 degrees.

You’ll need to adjust the width of the leg frame to adjust the angles. The bench top is 16 1/2″ wide so this leg will be as wide as the top which is just fine.

4. Cut notches for half lap joint

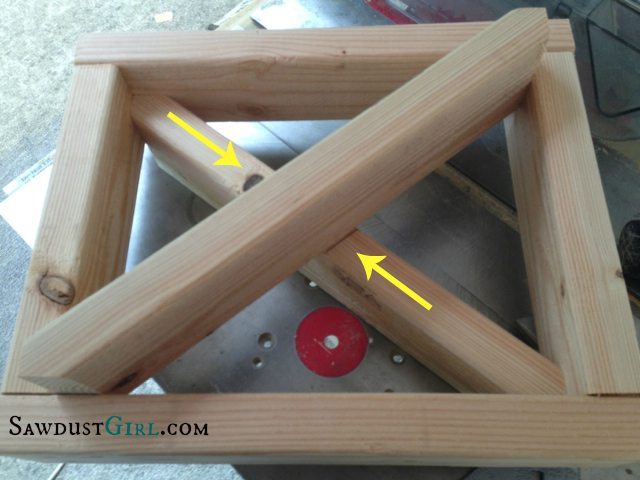

Once you have two X pieces cut, insert them into the box (they’ll only fit halfway in at this point) and mark where they cross. Mark one side then flip the entire leg over and mark the other side.

Cut out the wood where you just marked – but only halfway down on both boards — this creates a half lap joint.

To cut out the notches, I used my miter saw and made a series of cuts about 1/8″ apart from each other — just to the halfway mark on each board. Then I broke out the wood that was left.

Now the legs should fit together like this.

Once I created my fist half lap X and made sure it fit in the leg frame, I used one of the pieces as a template to mark the rest of the 8 boards that needed to be cut at angles and notched out for half lap joints.

Test each X in it’s frame and make sure everything fits before you start gluing up. Trim as needed.

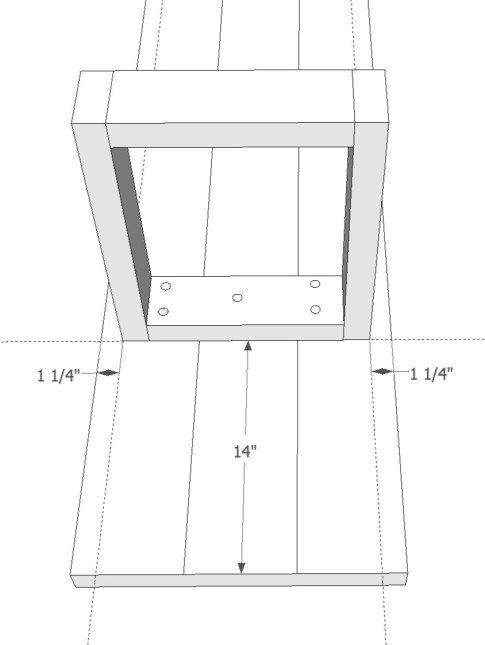

5. Attach leg frames to bench top.

Measure in 14″ from the ends and 1 1/4″ in from the front and back for leg placement.

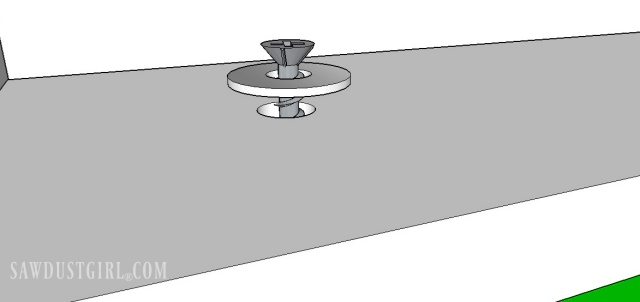

- Drill holes in the top of the leg that are larger in diameter than the 2 1/2″ screws.

- Use washers to keep the screw from pulling through the hole.

- This oversized hole will allow for wood movement which is especially important for outdoor furniture that will be exposed to frequent environmental changes.

6. Add X to leg frames

Apply glue to all the X angles that will contact the leg frame then insert the X into the frame. You might need to use a rubber mallet to help it into place. Drive one 2 1/2″ screw from the side of the frame into each end of the X to keep it in place.

7. Sand

Then I finished with my orbital sander making sure to round off all the edges to make it nice and comfy. This is a rustic bench so I’m not sanding perfectly or filling all the cracks and knots. I just want it smooth enough that no one gets any slivers.

8. Stain and Poly or Paint

I used exterior, satin black paint to finish my X leg bench.

I love the benches and the front porch now. It looks like a real home. You’d never know what chaos lies in wait once you walk through the front door — unless you happen to read my blog. 🙂

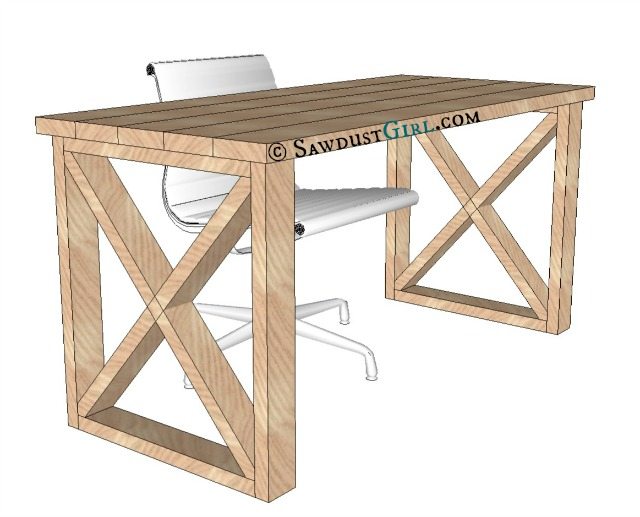

You might also like my plans for this X-leg desk!

I hope this isn’t a silly question.. We I have a ton of left over wood from pur deck, but it’s pressure treated. Do you think it’s Okay to use pressure treated or should we get different wood?

If you are making a bench for outside I don’t see an issue with using it. Use a good mask when cutting and sanding pressure treated lumber.

what kind of wood did you use for the project? I am planning to build this bench and put it outside. Will douglas fur wood for this?

Love the idea and the post. What kind of wood did you use? I went to lowes for wood and realized that the wood is pretty expensive. I looked at redwood and a single 2X4X8 itself costs about $10.

Loving the red color of your door. What color is it?

Absolutely love this post!! Making these benches this weekend – also my front door is already red – I’m gonna copy your whole design – where did u get your planters? Love all of it!